igus-icon-lupe

igus-icon-lupe

igus-icon-lupe

igus-icon-lupe

igus-icon-lupe

igus-icon-lupe

igus-icon-lupe

igus-icon-lupe

igus-icon-lupe

1 of 9

igus-icon-arrow-left

igus-icon-arrow-right

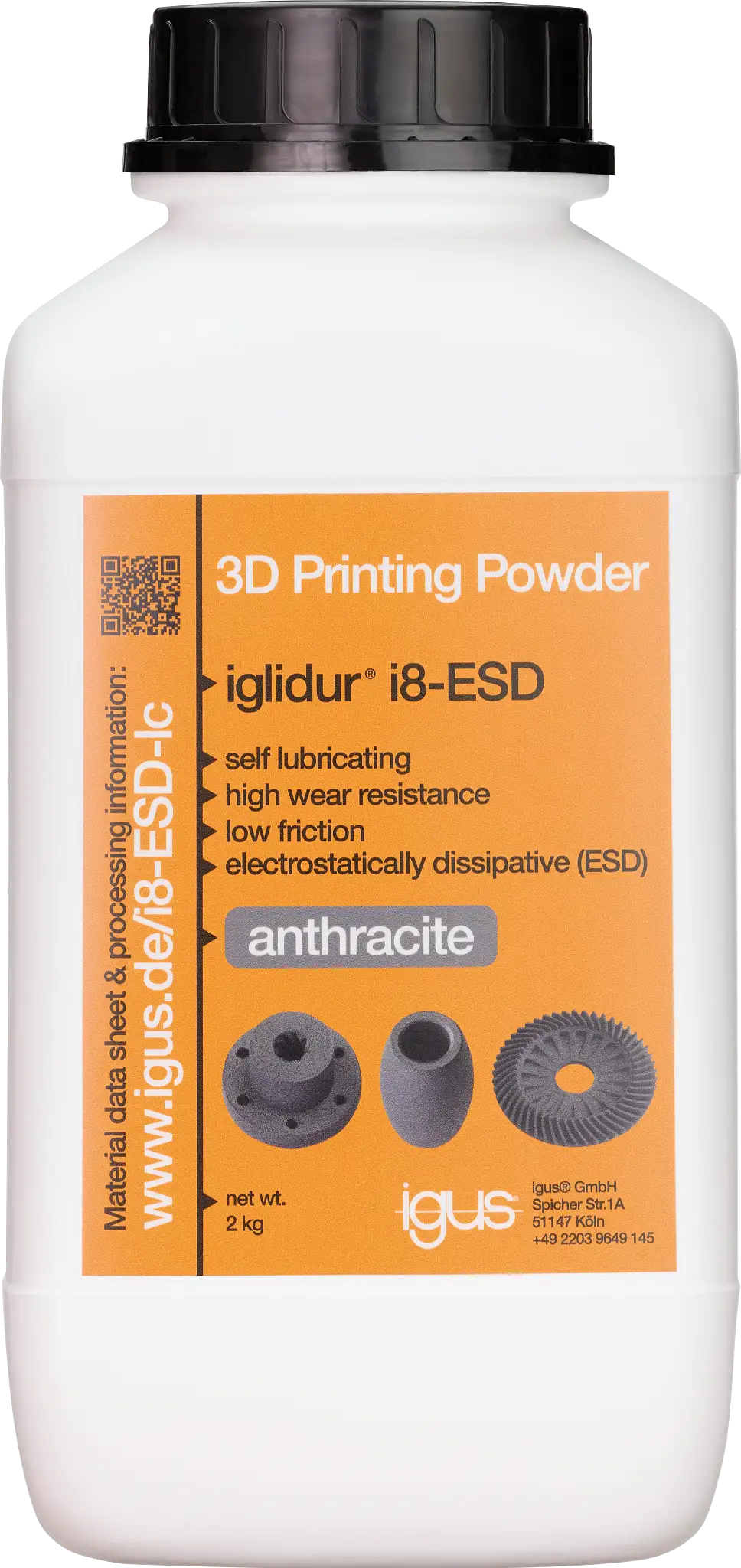

- Electrostatically dissipative (ESD)

- Dry-running and maintenance-free

- Excellent abrasion resistance

- Increased rigidity

- Can be processed on all SLS systems with and without CO2 laser

- Predictable service life

igus-icon-lieferzeit-dotI8-ESD-PL-2000

2000