Change Language :

How to Select the Bend Radius of a Cable Carrier

One of the most crucial factors is choosing the right bend radius for the cable carrier.

1.1 One of the most crucial factors is choosing the right bend radius for the cable carrier.

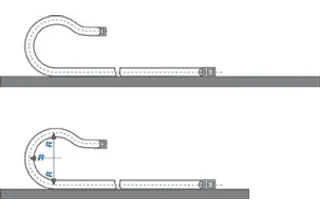

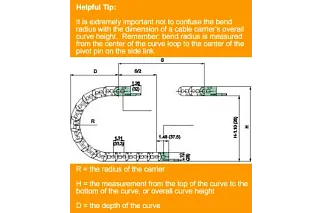

When specifying a cable management system, there are a number of different ways to maximize the service life of your cables and hoses. One of the most crucial factors is choosing the right bend radius for the cable carrier. It is important for the bend radius, with the exception of applications with space restrictions, to be larger than the recommended minimum bend radius of the cables and media that make up the fill package.

In a previous TechTalk, Caring for Cables, we discussed how all cable carriers have a predetermined radius stopping point on each link. When a number of links are assembled, these stopping points restrict the carrier from fully pivoting and form a curve loop, or minimum bend radius.

All cable carriers have multiple bending radii to choose from—igus®, for example, offers 12 different bending radii from stock—and every manufacturer suggests a minimum bend radius. The bending radius chosen for the cable carrier will depend on the cable or hose with the largest diameter. Selecting a considerably larger bend radius than required for the fill package will extend the lifespan of the cables and hoses.

1.2 The bending radius of the cable carrier depends on the cable or hose with the largest diameter.

General rules for selecting the bend radius

- Do not exceed the manufacturer’s suggested minimum bend radius; however, using the largest bend radius possible is optimal.

- If you do not know the recommended minimum bend radius of the cables in the fill package, follow these guidelines from NFPA 79 2007: “Cables with flexible properties subject to movement shall be supported in such a way that there is neither mechanical strain on the connection points nor any sharp flexing. When this is achieved by the use of a loop, it shall provide the cable with a bending radius of at least 10 times the diameter of the cable.”

The bending radius of the cable carrier depends on the cable or hose with the largest diameter.

- The larger the bend radius, the less stress is put on the cables and hoses, which will ensure longer service life.

- Keep in mind that the minimum bending radius is partly based on a temperature range for flexing. Special consideration is needed when the environment reaches or exceeds the temperature rating for the cable. This is especially true for low-temperature applications using thermoplastic cables, which tend to stiffen when exposed to the cold. Stiff cables can raise the radius of the cable carrier and lead to mechanical failures. Best practice is to use a cable with a low-temperature rated PUR or TPE jacket and / or consult the manufacturer for bend radius recommendations.

- In applications with severe space restrictions, the bend radius of the cable carrier may need to be smaller than the recommended minimum bend radius for the fill package. This is not ideal, but if it cannot be avoided, use cables specially designed for low-bend radius installations or consult your cable carrier manufacturer for the best solution.

Useful Links

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert