Change Language :

iglide® Coefficients of Friction

Coefficients of Friction

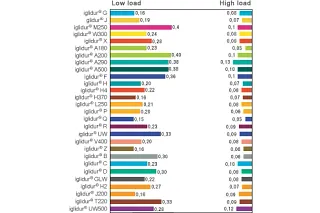

Figure 1.11: Coefficients of friction of iglide® plastic bushing materials under various loads

iglide® plastic bushings are self-lubricating due to being injection molded with solid lubricants. These solid lubricants lower each plastic bushing's coefficient of friction and increase its wear resistance.

Coefficient of friction µ measurement:

FR = μ x F

Depending on whether an application is starting from a standstill or the movement is in progress and needs to be maintained depends on whether the static or dynamic coefficient of friction is selected.

Coefficients of Friction and Surfaces

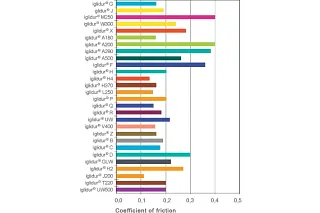

Figure 1.12: Coefficients of friction of different iglide® plastic bushing materials with each respective ideal shaft surface finish and low load: p = 108.75 psi

The relationship between coefficients of friction and the shaft surface finish is an interesting one. The amount of friction depends on different factors.

If the shaft is too rough, abrasion levels play a significant role. Small areas of unevenness that can interlock with each other must be worn off the surface.

If the surfaces are too smooth, however, higher adhesion results, i.e. the surfaces adhere to each other. Higher forces are necessary to overcome the adhesion, which results in an increased coefficient of friction. Stick-slip can be the result of a large difference between static and dynamic friction and of a higher adhesive tendency of mating surfaces. Stick-slip also occurs due to intermittent running behavior and can result in loud squeaking. Stick-slip thus represents a way in which plain bearings can malfunction. Time and again, it has been observed that such noises can be stopped or eliminated with rough shafts. Thus, for applications with the potential for stick-slip - slow movements, large resonance of the housings - attention must be paid to optimizing the roughness of the shafts.

Additional Technical Information

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert