Change Language :

Cable Festoon System vs. Cable Carrier

igus® alternative to a cable festoon system

On cable festoon systems, cables hang free and loose, exposed to the wind and weather. Unprotected, they can swing freely and become tangled, leading to costly maintenance efforts. Cable festoon systems typically require regular maintenance operations to lubricate the cable trolleys, and long travels can require motor and control systems. igus® offers a secure and modular alternative that allows you to save cables and avoid downtime. e-chain® cable carriers are ideal for industries such as port and terminal cranes, oil and gas and shorepower, as well as various applications for cranes such as bulkhandling cranes, ASC cranes, STS cranes, RTG/RMG cranes, and indoor cranes. Browse all crane applications.

White Paper: Efficient energy supply systems for cranes in steel plants

Learn the advantages of e-chains® vs. cable festoon systems.

In this white paper, you can find the following topics:

- Advantages and disadvantages of energy chain systems and cable festoon systems for steelworks cranes

- The most innovative solution for cranes for steel plants

- Future technologies: roller energy chains

What are the differences between e-chain® cable carriers and a cable festoon system?

Energy chain system

In the solution with cable carriers, the cables are fed into the e-chain® in the middle of the travel. The e-chain® is pushed or pulled to halfway.

Cable festoon system

In a cable festoon system, the cables are attached at the end of the travel and the cable loops are pulled all the way by the cable trolley.

Case Study: of a cable festoon system at a 100m plant

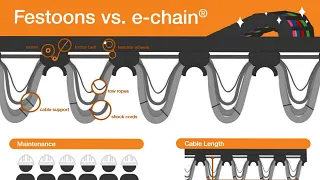

Cable Festoon System Infographic:

The Challenges of Cable Festoon Systems

Cable festoon systems have been a staple in crane operations for many years, but as demands for faster installation, increased flexibility, and improved technology have grown, the drawbacks of cable festoon systems have become apparent.

Alternative cable festoon system products

Replacement cable festoon system applications

8 Common questions when considering a cable festoon system

- Traditional cable festoon systems can be prone to entanglement during operation, leading to downtime, and they require huge lengths of cable, taking up a great deal of space and needing protective cladding, which increases the mechanical stress on the cables

- Cable festoon systems consume space on the crane rail, limiting the amount of crane travel that can be accomplished, and the structure makes cable replacement or addition a time-consuming process.

- Unprotected cables in festoon systems can swing, become tangled, and get caught in the crane structure, especially during harsh weather, leading to costly repairs and downtime.

- Cable festoon systems require approximately 115% of the travel length in cable, while energy chain systems require about 50% less cable, reducing mechanical stress and system weight.

- Cable festoon systems have to be specially protected in harsh environments, increasing the total weight of the system and the steel structures required to bear the large cable lengths and the cable junction.

- Cable carriers can lead to lower operational costs and increased energy savings due to their energy-efficient design and reduced maintenance requirements. In contrast, cable festoon systems have limits with regard to energy efficiency and service life, requiring higher energy input and maintenance costs..

- The low wear properties of cable carriers ensure a high service life and minimize maintenance requirements and downtime, while cable festoon systems have suboptimal wear behavior, increasing the need for maintenance and potentially causing system downtime in the long term.

- Cable carriers, made from tribologically optimized polymers, ensure a high service life and minimize maintenance requirements and downtime, providing a durable and low-cost solution for industrial crane systems. In contrast, cable festoon systems have proven to have limits with regard to energy efficiency and service life, requiring extensive protective cladding and being relatively heavy.

System Comparison:

Energy chain systems instead of busbar systems

Deliver data, energy, fluids and air safely in a single energy chain system. For narrow compact spaces and fast lane movement.

More crane technology information

Discuss your project with an expert!

Whether you're interested in end-to-end, fully assembled solutions or looking to build your own customizable project, let us assist you with a solution based on your specific application and requirements. Contact us via the form below or call us at (800) 521-2747 to discuss your project today!