Change Language :

Overhead Crane Busbar System vs. e-chain®

Faster, smarter alternative to an overhead crane busbar system

For facility managers and engineers in the material handling and automation industries, the biggest headache is often the inefficiency and high maintenance demands of traditional crane busbar systems. These systems, while common, are notorious for their rigidity, frequent breakdowns, and limited functionality restricting energy transmission to just power, with no capacity for data or fluid transmission. Busbar systems make it challenging to keep your operations running smoothly due to unexpected maintenance, costly downtime and the safety risks that come with outdated power distribution systems. The inability to transmit data or fluids alongside power in a compact, efficient manner further compounds the challenge, leaving you stuck in a cycle of reactive maintenance, with your productivity and profitability taking the hit. This isn’t just inconvenient; it’s a threat to the sustainability of your operations.

Don't let outdated technology hold your operations back any longer. Make the switch to an e-chain® system today and experience the difference in power distribution that propels you ahead of the competition. Contact us today to schedule a free consultation and see the e-chain system in action.

Consider the facts before using a busbar system in your application.

TechTalk: Overhead crane electrical busbars vs e-chains®

Get an in-depth look into busbar systems and e-chains®, read this tech talk and consider the facts before deciding which system will best suit your application.

What are the differences between e-chain® and an overhead crane busbar system?

e-chain® system

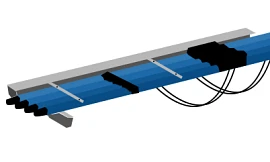

In the solution with cable carriers, the cables are fed into the e-chain® in the middle of the travel. The e-chain® is pushed or pulled to halfway.

Crane busbar system

Busbars are high maintenance systems that require a lot of care and adjusting.

System Comparison: of an overhead crane busbar system

White Paper: e-chain® with steel-rope guide vs electrical busbar?

Consider the facts before deciding which system is best for your application.

While busbars are a common solution for energy transfer in moving applications across long distances, the autoglide 5 from igus® is a worthy alternative that offers features not possible with busbars.

Alternative overhead crane busbar system products

System Comparison:

Energy chain systems instead of festooning

Provide guidance for cables and energy chains while keeping them protected and safe in wind and fluctuating temperatures. This minimizes downtime.

More crane technology information

FAQ

Busbars are horizontal metal conductors used to supply power along the runway or bridge of a crane through steel or copper conductor bars. A collector arm slides along the conductor bar, allowing current to pass from the electrified conductor bar to the moving collector and on to the moving hoist or other traveling element.

Busbars require frequent inspection and maintenance, leading to downtime for the crane system. The collector shoes installed on the collector arms need to be regularly inspected and replaced when they wear out, requiring the system to be powered down for maintenance. Additionally, busbars are limited in the complexity and type of energy they can supply. This can expose bare loaded conductors to the surrounding environment, causing serious safety concerns, especially in hazardous or explosive environments.

Busbars are limited to power or occasionally control circuits, and adding additional components may require a full rebuild of the cable management system. They are also restricted to the transfer of electricity, which may not be sufficient.

Busbars are not suitable for areas with strict hygiene requirements, cleanroom environments, or environments with explosive and highly flammable products.

An e-chain® is suitable for long travels up to 1,000m and is proven to withstand the most demanding environments. This addresses the safety concerns associated with busbars and makes it suitable for a wide range of applications.

Unlike busbars, the e-chain® system can guide energy, data, air, and liquids all in one system, making it suitable for the transfer of electricity as well as data transfer, such as for Ethernet, sensors, and camera systems, which is essential in the era of Industry 4.0.

e-chains® require significantly less installation time and effort compared to busbars, reducing overall setup costs and complexity.

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert