drylin® W Linear Rails & Carriages

Browse the shop to discover the drylin® W linear rails and carriages product line. Single and double rails are available with round, curved or square variants, each with accompanying carriages and pillow blocks. drylin® W linear bearings are dry-running, eliminating the need for external lubrication or grease, which could otherwise cause dirt or dust adhesion. They’re also up to four times quieter than comparable metal bearings due to a lower coefficient of friction. Learn more about drylin® W products here. Only available in metric measurements

drylin® W double rail WS

- Easy to assemble

- No rail cutting charge

- Design: Double Rail

- Material: Aluminum, hard anodized

- Rail profile: Round

drylin® W single rail WS

- Single rail

- Round

- Hard-anodized aluminum

- Design: Single Rail

- Material: Aluminum, hard anodized

- Rail profile: Round

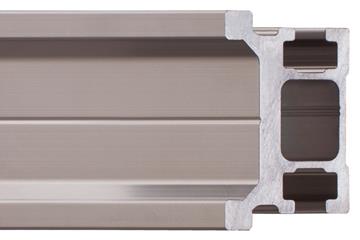

drylin® W double rail WSQ

- Design: Double Rail

- Material: Aluminum, hard anodized

- Rail profile: Square

drylin® W-Econ double rail WS-CA

- Suitable for all drylin® W single bearing housings and linear carriages

- Lifelong rattle-free due to combination with pre-loaded drylin® W linear bearings series WJ200UM-01-Pxx

- Individual bearing clearance adjustment by using WJ200UME-01 bearing housings

- Design: Double Rail

- Material: Aluminum

- Rail profile: Round

drylin® W single rail WSQ

- Design: Single Rail

- Material: Aluminum, hard anodized

- Rail profile: Square

New

drylin® W-Econ single rail WS-CA

- Suitable for all drylin® W single bearing housings and linear carriages

- Lifelong rattle-free due to combination with pre-loaded drylin® W linear bearings series WJ200UM-01-Pxx

- Individual bearing clearance adjustment by using WJ200UME-01 bearing housings

- Design: Single Rail

- Material: Aluminum

- Rail profile: Round

drylin® W double rail WSX

- Design: Double rail high profile

- Material: Aluminum, hard anodized

- Rail profile: Round

drylin® W Clip-type linear carriage with clamping CC

- Clamping of the linear carriage as protection against vibration and unintentional adjustment

- Clip-on mechanism for installing in place

- Easy adjustment due to tribo-optimised liners

- All components are recyclable

- Design: round

- Material sliding element: iglide® I3

- With manual clamp

- Material: Aluminum

drylin® W double rail, WSXQ

- Design: Double rail high profile

- Material: Aluminum, hard anodized

- Rail profile: Square

drylin® W double rail WS-ES

- Design: Double Rail

- Material: stainless steel 1.4571

- Rail profile: Round

drylin® W single rail WS-ES

- Design: Single Rail

- Material: stainless steel 1.4571

- Rail profile: Round

drylin® W assembled carriage plate WW

- Design: round

- Material sliding element: iglide® J

- Material: Die-cast zinc

drylin® W double rail, WSPC (CWS, USA)

- **Material: Carbon Fiber**

- Design: Double rail high profile

- Material: Carbon

- Rail profile: Square

drylin® W assembled carriage plate WW-HKA

- Design: round

- Material sliding element: iglide® J

- With manual clamp

- Material: Die-cast zinc