Change Language :

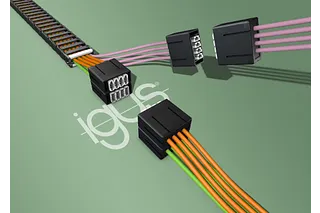

Module Connect adapter for easy connection of e-chain® cable carriers

Standard version: black (other colors available on request)

Saves assembly time

The new Module Connect adapter is specially designed to make the interface concept, Module Connect, and to make the connection of the energy chain with the cables inside it even easier. The harnessed e-chain is an interconnected system and can be installed directly.

The e-chain and the Module Connect are standardized. Depending on the chain series, chain width and number of Module Connect connectors, a matching chain adapter is produced using 3D printing. (The possibility of a plastic injection molding can also be explored.) The adapter is simply assembled to the Module Connect and can be attached to the chain using the snap-in mechanism .

As a result, the entire assembly of a readychain standard including Module Connect is an interconnected system, i.e. pin assignment and cable lengths are clearly defined.

Fast assembly

For this purpose, we have developed the Module Connect adapter