Change Language :

iglide® B180 gears

Save weight and costs with injection molded iglide gears

iglide materials are characterized by a particularly low coefficient of friction, high wear resistance - even in applications with continuous operation - and their vibration-dampening specifications. These advantages can now also be used for gears: cost-effectively injection moulded from iglidur materials, they make the use of additional lubricants superfluous and your application is therefore maintenance-free.

Proven in continuous operation

We have developed iglide gears for this purpose

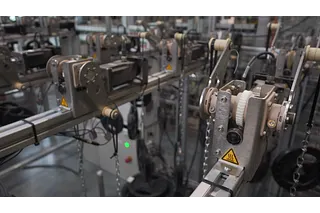

The iglide gears have proven themselves many times in our robolink gearboxes and have additionally been tested in the igus test laboratory under real operating conditions. For example, torque fluctuations, efficiency and backlash of the gearboxes with the iglide gears are electrically measured and evaluated here. The gathered experience values allow a continuous optimisation of our gears and the use in wear-intensive continuous application.

iglide gears are characterised by their special wear resistance in use. Due to their special material composition of base polymers, fibres and fillers as well as solid lubricants, they have very low wear properties and do not require additional lubricants. This extends maintenance intervals and reduces expensive downtime minutes.