Change Language :

chainflex® cables & hoses for cleanroom applications

Having abrasion-resistant cables that meet cleanroom standards are essential in semi-conduction manufacturing, since the ISO norm 14644-1 comes into effect. ISO norm 14644-1 categorizes how many particles of <3µm are allowed to be contained in 1m3air into 9 different classes. These particles can damage the product that will be manufactured, increasing the scrap rate, so ensuring that all equipment being used with a clearoom is resistant to abraions is key.

Cleanrooms are not only found in semiconductor manufacturing, but also in laboratories, medical technology and the pharmaceutical industry—wherever meticulous cleanliness is essential. As our quality demand keeps increasing, the demand for this kind of production is also growing. Just think about how many cables are involved within the production of large flat-screen TVs, where any pixel errors are unacceptable. The same applies to vaccine cannulas, which have to be produced with precision and under hygienic conditions. If moving parts such as cable carriers are installed with flexible cables running inside, they have to be set up in a manner that reduces abrasion to minimal amounts, or the particles that develop during manufacturing, or emitted by the outside, have to be removed from the ambient air, which can be extremely costly. By using cables with low abrasion, i.e. few particles, the cumbersome and expensive removal of air particles is no longer necessary.

400 million cycles for pick and place machine

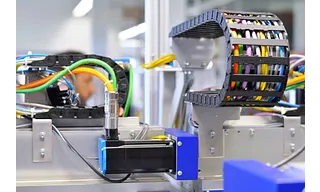

The company Assembléon Netherlands B.V. has developed a new generation of fully automatic pick and place machines of the series iFlex T4, T2 and H1 with vision system. They can be used for low and high volumes. The SMD assembly is carried out by robots on one or both sides in serial quality for components from a size of 0402. The part handling is between 51,000 (T4) and 12,000 (H1) per hour. The acceleration and the speed are on the one hand 35m/s2 (y-axis) and 20m/s2 (x-axis), and on the other hand 2m/s and 1.5m/s. Required service life of the respective components is 400 million cycles, which corresponds to approximately seven years of continuous operation.

Discuss your project with a flexible cable expert

Whether you're interested in turnkey, fully assembled solutions or looking to build your own customizable project, let us assist you with a solution based on your specific application and requirements. Contact us via the form below or call us at (800) 521-2747 to discuss your project today!