Inquiry / Contact

igus® inc.

| General features | Unit | iglide® UW | Test method | |

| Density | g/cm³ | 1.52 | ||

| Color | Black | |||

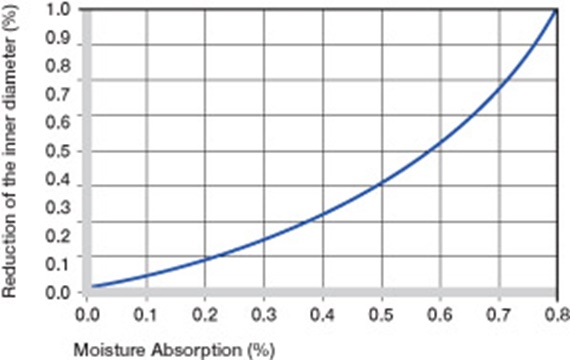

| Max. moisture absorption at 73° F/50% R. H. | Wt.-% | 0.2 | DIN 53495 | |

| Max. moisture absorption | Wt.-% | 0.8 | ||

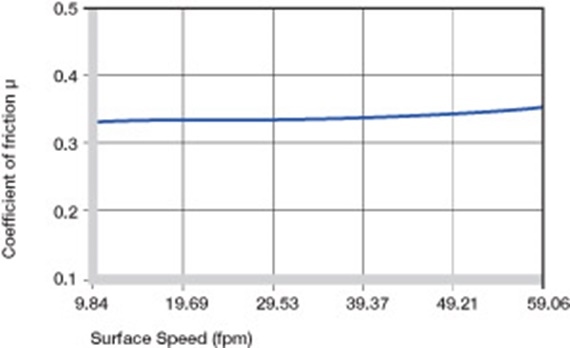

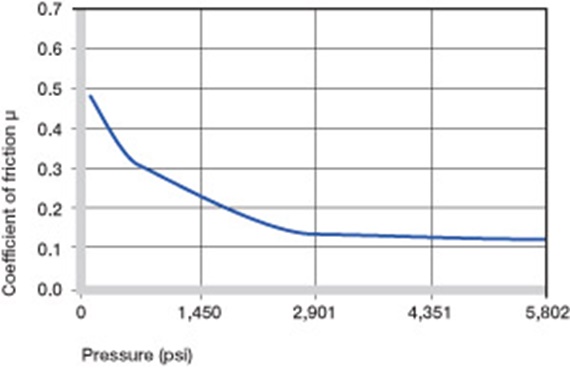

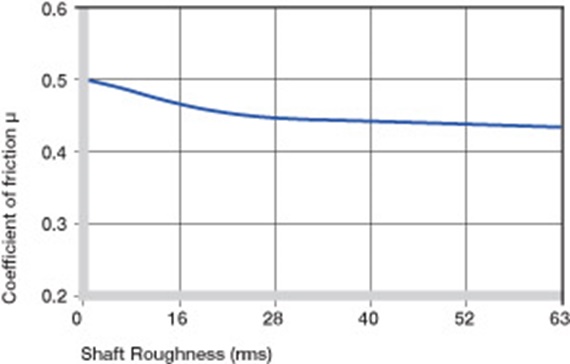

| Coefficient of friction, dynamic against steel | µ | 0.15 - 0.35 | ||

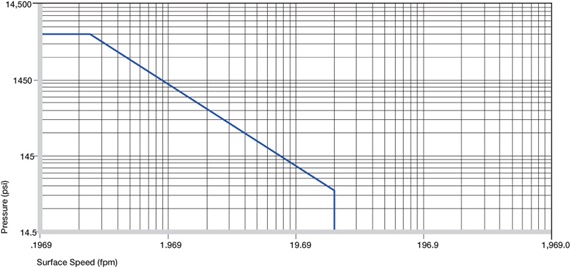

| p x v value, max. (dry) | psi x fpm | 2,800 | ||

Mechanical properties | ||||

| Modulus of elasticity | psi | 1,392,000 | DIN 53457 | |

| Tensile strength at 68° F | psi | 13,050 | DIN 53452 | |

| Compressive strenght | psi | 10,150 | ||

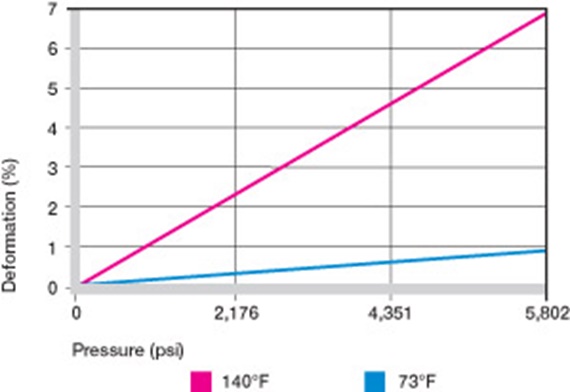

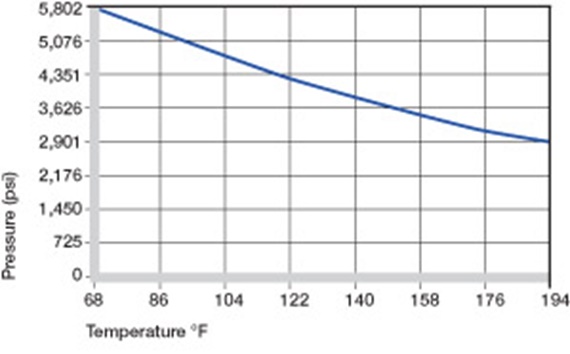

| Permissible static surface pressure (68° F) | psi | 5,802 | ||

| Shore D hardness | 78 | DIN 53505 | ||

Physical and thermal properties | ||||

| Upper long-term application temperature | °F | 194 | ||

| Upper short-term application temperature | °F | 230 | ||

| Lower application temperature | °F | -58 | ||

| Thermal conductivity | [W/m x K] | 0.60 | ASTM C 177 | |

| Coefficient of thermal expansion (at 73° F) | [K-1 x 10-5 ] | 6 | DIN 53752 | |

Electrical properties | ||||

| Specific volume resistance | Ωcm | < 10 5 | DIN IEC 93 | |

| Surface resistance | Ω | < 10 5 | DIN 53482 | |

| fpm | Rotating | Oscillating | Linear |

| Constant | 98 | 78 | 393 |

| Short-term | 295 | 216 | 590 |

| iglide® UW | Application temperature |

| Lower | - 58 °F |

| Upper, long-term | + 194 °F |

| Upper, short-term | + 230 °F |

| Additional axial securing | + 176 °F |

| iglide® UW | Dry | Grease | Oil | Water |

| Coefficients of friction µ | 0.15 - 0.35 | 0.09 | 0.04 | 0.04 |

| Diameter d1 [inch] | Shaft h9 [inch] |

iglide® UW E10 [inch] |

| Up to 0.019685 | 0 - 0.0009843 | +0.000551 + 0.0021260 |

| > 0.1181 to 0.2362 | 0 - 0.0011811 | +0.000787 + 0.0026771 |

| > 0.2362 to 0.3937 | 0 - 0.0014173 | +0.000984 + 0.0032677 |

| > 0.3937 to 0.7087 | 0 - 0.0016929 | +0.001260 + 0.0040157 |

| > 0.7087 to 1.1811 | 0 - 0.0020472 | +0.001575 + 0.0048819 |

| > 1.1811 to 1.9685 | 0 - 0.0024409 | +0.001969 + 0.0059055 |

| Medium | Resistance |

| Alcohol | + to 0 |

| Hydrocarbons, chlorinated | + |

| Greases, oils, without additives | + |

| Fuels | + |

| Weak acids | 0 to - |

| Strong acids | - |

| Weak alkaline | + |

| Weak alkaline | + to 0 |

| Specific volume resistance | > 105 Ωcm |

| Surface resistance | > 105 Ω |