Change Language :

ESD cable carriers made from Shock-Resistant Materials

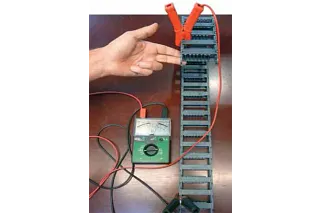

100% of the produced ESD e-chains® are checked for their continuous conductivity "from one end to the other"

100% of the produced ESD e-chains® are checked for their continuous conductivity "from one end to the other"

Conductivity of igus® products made of igumid ESD

Contrary to the conductive surface coatings for temporary use or the briefly incorporated static inhibitors, the applied additive enables a lasting and maintenance-free conductivity for years. However to ensure conductivity in an e-chain®, it is not enough if only the individual components exhibit conductivity, but the entire e-chain® must have a continuous conductivity from one end to the other. All products in this catalog are optimized in this regard, and the continuous conductivity is measured and documented by a 100% test before delivery.

Only the e-chains® that have passed this test are given the seal and delivered. The color of the igumid ESD products is similar to RAL7015, slate gray for safe differentiation from standard materials.

Structural design

Not only the material is important for a safe electrostatic discharge. The structural design is also critical for a truly safe use. The e-chains® from the E4.1 modular kit ensure a permanently constant discharge, since its chain links have a positive-fit connection with each other. Through its patented "tongue and groove" system, the inner link engages the outer link, whereby a discharge is guaranteed even after several million cycles. The e-chains® from the E2/000 range ensure a safe discharge due to the extremely low clearance between the pin and the hole of the chain links.

Material table igumid ESD

| Material data igumid ESD | Measuring unit | Values igumid ESD |

|---|---|---|

| Mechanical properties | ||

| Tensile stress at yield (dry/wet) | MPa | * |

| Elongation at break (dry/wet) | % | * |

| Elasticity module (tensile test) | MPa | * |

| Limit of elasticity in bending | MPa | 9.500 |

| Bending strength | MPa | 230 |

| Hardness Shore D | - | 83 |

| General features | ||

| Density | g/m^3 | 1,2 |

| Absorption of humidity 23/50 RF | Wt.-% | 1,9 |

| Maximum water absorption | Wt.-% | 7,3 |

| Electrical properties | ||

| special transitional resistance | Ω*cm | <10^9 |

| Surface resistance ROA | Ω | <10^9 |

| Thermal properties | ||

| Lower application temp. | °C | -40°C / -40°F |

| Upper long-term application temp. | °C | 80°C / 176°F |

| Upper short-term application temp. | °C | 150°C / 302°F |

| Material verification | ||

| Fire behavior according UL94 | – | HB |

| Silicon-free | – | Yes |

| Halogen-free | – | Yes |

| 2002/95/EG (RoHS) | – | Yes |

| 2002/96/EG (WEEE) | – | Yes |

| Color | ||

| According to RAL, approximate | – | ≈RAL7015 |

| *Values on inquiry |

Certification of igus® materials:

- 1992 Test certificate from the PTB for igumid GC in explosion protection zones 0, 1 and 2.

- 1998/1999 Additional certifications by the PTB according to DIN and static electricity guidelines.

- 2002 igumid ESD is released in gray (for clear distinction) by the PTB after tests lasting 100

million cycles.

More information of ESD

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert