Change Language :

3D printing innovations in 2023

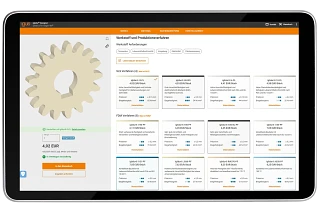

One-for-all online tool for 3D printing service

Simple and fast print of functional components

With the update of the 3D printing service tool, users can now get all the information they need regarding price, manufacturability and delivery time as well as material properties, expected service life and finishing of individual components easily in one tool. Discover new materials and features as well as optimisations in reworking and finishing.

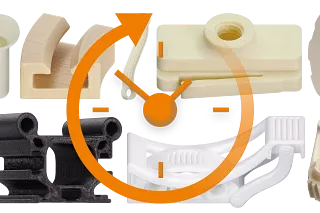

Service life calculator for custom components

Calculate component service life for each material online now

The service life calculation integrated into the 3D printing service tool allows for a very easy service life calculation for individual components in sliding applications, based on the results of thousands of wear tests from the igus test laboratory every year. Simply click on sliding surface and enter the parameters. The service life (in hours) will be displayed for each available material. This helps increase system reliability and prevent unnecessarily early requirements for replacement parts.

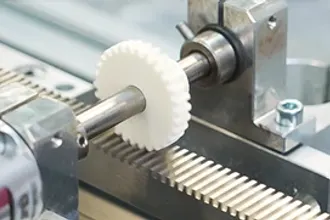

Resin 3D printing with Digital Light Processing (DLP)

iglidur® i3000 3D printing resin with increased stability for wear-resistant parts

iglidur® i3000 gives igus the world's first resin developed specifically for DLP 3D printing of wear-resistant parts and gears. The mechanical specifications have now been improved by 50%, so that the parts made of synthetic resin, which are hardened in layers using UV light, are characterised by finest details and a substantial service life. Available as a material in the shop and now also in the online 3D printing service.

Laser-sintering material for high-temperature applications

iglidur® i230 PFAS-free laser-sintering powder

The new iglidur® i230 withstands long-term temperatures of up to 110° Celsius. In addition, the material is 80% more wear-resistant than standard PA12. Compared to all laser-sintering materials from igus, iglidur i230 also offers the highest flexural strength. The material is available in the shop and can be ordered in the 3D printing service in 5 to 10 days. Become a beta tester of iglidur i230 now and request a sample.

ESD material for sensitive electronic components

iglidur® i9-ESD SLS powder with medium conductivity

With its electrical resistance of 106 to 109ohms, the SLS powder is electrostatically dissipative while reducing the risk of unwanted discharge currents between sensitive electrical components. This makes it ideal for applications in the electronics and semiconductor industries. It is available as a material in the shop and in the 3D printing service in five to ten days.

ESD material for low-cost laser sintering systems

iglidur® i8-ESD SLS powder in 2kg container

iglidur® i8-ESD is an electrostatically dissipative SLS material for durable, abrasion-resistant 3D printing components that can be processed on all SLS systems with and without a CO2laser. The consistently black powder is now also available in 2kg containers for processing on low-cost systems.

For more productivity in 3D printing

iglidur® i150 tribofilament® on a 2kg-spool

Our easy-to-process all-rounder filament iglidur® i150 is now available on a 2kg spool. Spool changes are no longer necessary when printing particularly large or multiple components in one process, which greatly increased productivity.

More information about igus® 3D printing

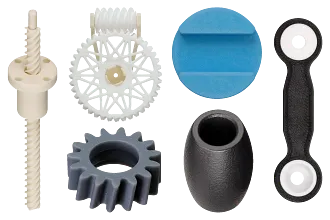

Additive manufacturing

Find out more about 3D printing with wear-resistant plastics at igus.

3D printing materials

Discover our other abrasion-resistant plastics for industrial use.

Tested!

3D printing materials made of iglidur compared to PLA, ABS and other materials and manufacturing processes.

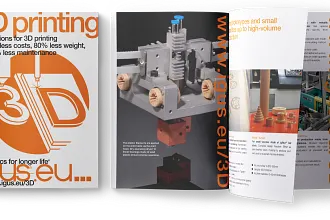

Industry brochure

Receive information about all solutions that igus® offers for additive manufacturing.