Change Language :

Smooth, quiet, long service life

New dryspin® dimensions: extension of the sliding and high helix thread product range

The high helix lead screws are part of our dryspin® range, which is specifically designed for fast and very efficient applications. Here, thread sizes from DS4x2.4 to DS18x100 are available. The lead screw product range also offers small pitches with the well-known dryspin® advantages.

► Vibration-free and quiet operation

► Lead screw machining online without previous CAD knowledge

► Service life of lead screw drives predictable online

► Desired length without waste

► Up to 30% longer service life due to thread asymmetry

Reduce the time required for your design and streamline the procurement process for your lead screw technology.

Expansion of the product range of dryspin® lead screw nuts made of bar stock

By three new dimensions

The dryspin® lead screw technology is based on the principle of lubrication-free and maintenance-free linear technology. The specifications and geometries of our lead screw technology, which are matched to the plastic nut and lead screw, guarantee efficiencies of up to 82% and a service life that is up to 30% longer than conventional lead screw drives

► New dryspin® lead screw nuts

► Pitches DS8x2 RH, DS10x2 LH and DS20x50 LH

► Up to 50.9% more cost-effective than metal lead screw nuts

► FDA-compliant materials available

► Smoother operation thanks to tight manufacturing tolerances

Reduce the time required for your design and optimise the procurement process for your lead screw technology.

Product range expansion of the dryspin® injection moulded lead screw nuts

By two new dimensions

The dryspin® lead screw technology is based on the principle of lubrication-free and maintenance-free linear technology. The specifications and geometries of our lead screw technology, which are matched to the plastic nut and lead screw, guarantee efficiencies of up to 82% and a service life that is up to 30% longer than conventional lead screw drives.

► Longer service life thanks to the injection-moulding process

► Pitches DS8x2 RH and DS10x2 LH

► Up to 50.9% more cost-effective than metallic lead screw nuts

► Long-lasting use thanks to patented asymmetry

► Quiet operation due to rounded thread geometry

Reduce the time required for your design and optimise the procurement process for your lead screw technology.

Minimum axial clearance

Clearance-reduced pre-load lead screw nuts

The pre-load lead screw nut convinces with minimal axial clearance and highest positioning accuracy. It is the cost-effective alternative to the zero backlash lead screw nuts and perfectly suited for small pitches. This is the proven preload principle from SHT-PL.

► Permanently minimal axial clearance for high positioning accuracy

► More cost-effective than ZB nut due to fewer components & injection moulding

► Reduced axial clearance due to spring pre-load on the lead screw nut

► No lubricating grease or oil in the lead screw drive

Reduce the time required for your design and optimise the procurement process for your lead screw technology.

2022

The new floating bearing plastic lead screw support blocks

The latest design study

▲ Tech up:

New lead screw support block design in four new sizes for easy mounting of lead screw drive

Easy installation

▼ Cost down:

Cost-effective type optimised for injection moulding

Cost savings of up to 60% compared to commercially available metallic lead screw support blocks with the same connection dimensions

This study combines stiffened plastic blocks with a metallic clamping ring and iglidur plain bearings for the fixed bearing version and only the plastic blocks with an iglidur special slider for the floating bearing version. 100% same dimensions as metallic lead screw support blocks.

The new fixed bearing plastic lead screw support blocks

The latest design study

▲ Tech up:

New lead screw support block design in four new sizes for easy mounting of lead screw drive

Easy installation

▼ Cost down:

Cost-effective type optimised for injection moulding

Cost savings of up to 60% compared to commercially available metallic lead screw support blocks with the same connection dimensions

This study combines stiffened plastic blocks with a metallic clamping ring and iglidur plain bearings for the fixed bearing version and only the plastic blocks with an iglidur special slider for the floating bearing version. 100% same dimensions as metallic lead screw support blocks.

New pitches of the dryspin® lead screws

Two new dimensions

▲ Tech up:

High efficiency

Smoother running due to tighter manufacturing tolerances in standard

Quiet operation thanks to rounded tooth geometry

▼ Cost down:

Online tool for lead screw configuration

Instant price display

Lead screw machining online without previous CAD knowledge

Higher efficiency and longer service life than conventional lead screws thanks to the unique dryspin® lead screw technology. Corrosion-free and 100% lubrication-free and maintenance-free. Our dryspin® lead screws are now available in four new dimensions.

New pitches of the dryspin® machined lead screw nuts

Two new dimensions

▲ Tech up:

Lead screw nuts in cylindrical type or with flange

Smoother operation due to tighter manufacturing tolerances in standard

Quieter operation thanks to rounded tooth geometry

▼ Cost down:

100% lubrication-free and maintenance-free

Up to 50.9% more cost-effective than metallic lead screw nuts

Free online tools with service life calculation and instant price

Efficiencies of up to 82% and 25% less wear than conventional lead screw drives. Discover the advantages of the lubrication-free polymer alternative to metallic ball screws here. Our plastic lead screw nuts are now available in two new dryspin® thread pitches.

New pitches of the dryspin® injection moulded lead screw nuts

Two new dimensions

▲ Tech up:

Quiet operation thanks to rounded tooth geometry

Longer service life due to injection moulding processes

Smoother running due to tighter manufacturing tolerances in standard

▼ Cost down:

Cost-effective production using injection moulding

100% lubrication-free and maintenance-free

Up to 50.9% more cost-effective compared to metallic lead screw nuts

Longer service life thanks to injection moulding processes and smoother operation due to tighter manufacturing tolerances. Discover the advantages of the injection-moulded polymer alternative to metallic ball screws here. Our dryspin® injection moulded lead screw nuts are now available in two new dimensions.

The new dimensions of the dryspin® preload lead screw nut

For dryspin® threads with 6.35 and 10 diameter sizes

▲ Tech up:

Cost-effective alternative to zero backlash nut

Permanent minimum axial clearance for high positioning accuracy

Proven pre-load principle from SHT-PL

▼ Cost down:

100% lubrication-free and maintenance-free

No maintenance work thanks to self-adjusting axial clearance on both sides

The new pre-load lead screw nut impresses with minimum axial clearance and maximum positioning accuracy. It is the cost-effective alternative to the zero backlash and ideally suited for small pitches. This is the proven pre-load principle from SHT-PL. Typical applications include 3D printers.

New pitches of the dryspin® lead screws

Four new dimensions

▲ Tech up:

Alternative to DIN103

Smoother running thanks to narrower manufacturing tolerances in the standard

Low-noise operation thanks to rounded tooth geometry

▼ Cost down:

Online tool for lead screw configuration

Live price display

Lead screw machining online without prior CAD knowledge

Higher efficiency and longer service life than conventional lead screws thanks to unique dryspin® lead screw technology. Corrosion-free and 100% lubrication-free and maintenance-free. Our dryspin® lead screws are now available in four new dimensions.

New pitches of the dryspin® bar stock lead screw nuts

Four new dimensions

▲ Tech up:

Alternative to DIN103

Smoother operation thanks to narrower manufacturing tolerances in the standard

Low-noise operation thanks to rounded tooth geometry

▼ Cost down:

100% lubrication-free and maintenance-free

Up to 50.9% more cost-effective compared with metal lead screw nuts

Free online tools with service life calculation and live price display

Efficiencies of up to 82% and 25% less wear than conventional lead screws. Discover the advantages of the lubrication-free polymer alternative to metallic ball screws here. Our plastic lead screw nuts are now available in four new dryspin® thread pitches.

New pitches of the dryspin® injection moulded lead screw nuts

Four new dimensions

▲ Tech up:

Alternative to DIN103

Longer service life thanks to injection moulding

Smoother operation thanks to tighter manufacturing tolerances in standard

▼ Cost down:

Cost-effective injection moulding

100% lubrication-free and maintenance-free

Up to 50.9% more cost-effective compared to metallic lead screw nuts

Longer service life thanks to injection moulding and smoother operation thanks to tighter manufacturing tolerances. Discover the advantages of the injection-moulded polymer alternative to metallic ball screws here. Our dryspin® injection moulded lead screw nuts are now available in four new dimensions.

dryspin® motor lead screws with serration

With a fixed length of 1,000mm

▲ Tech up:

Expansion of the dimensional range for motor lead screws

Ready for connection to drylin® E serrated motors

Transmission of larger torques possible

▼ Cost down:

No additional configuration required

Free online tools with service life calculation

Lead screw machining online without prior CAD knowledge

Higher efficiency and longer service life than conventional motor lead screws thanks to the unique dryspin® lead screw technology. Corrosion-free and 100% lubrication-free and maintenance-free. Our dryspin® motor lead screws with serrations for drylin® E motors are now available in twelve dimensions and with the following specifications.

dryspin® motor lead screws with machined ends

With a fixed length of 310mm

▲ Tech up:

Expansion of the range of dimensions for motor lead screws

Ready-to-connect for drylin E lead screw motors

▼ Cost down:

No additional configuration required

Lead screw machining without prior CAD knowledge

Free online tools with service life calculation

Higher efficiency and longer service life than conventional lead screws thanks to the unique dryspin® high helix thread technology. In the standard range for motor lead screws, you receive ready-to-connect thread dimensions from DS6.35x2.54 to DS14x25 and TR08x1.5 to TR12x6P3. Accordingly, our dryspin® motor lead screws with precision machined ends for drylin® E motors are available in 24 dimensions.

The new dryspin® preload lead screw nut

For dryspin® thread with diameter size 6.35

▲ Tech up:

Cost-effective alternative to zero backlash nut

Permanent minimum axial clearance for high positioning accuracy

Proven pre-load principle from SHT-PL

▼ Cost down:

100% lubrication-free and maintenance-free

No maintenance work thanks to self-adjusting axial clearance on both sides

The new pre-load lead screw nut impresses with minimum axial clearance and maximum positioning accuracy. It is the cost-effective alternative to the zero backlash and ideally suited for small pitches. This is the proven pre-load principle from SHT-PL. Typical applications include 3D printers.

The new dryspin® zero-backlash lead screw nut

To reduce axial clearance

▲ Tech up:

Higher axial loads up to 500N

Load-independent

Minimum axial clearance for life thanks to zero backlash principle

▼ Reduce costs:

No maintenance work thanks to self-adjusting zero backlash principle

Free online tools with service life calculation

Up to 82% higher efficiency

To reduce axial clearance, one of the most precise solutions is the zero backlash lead screw nut. It consists of several components and adjusts itself to the service life. It is particularly suitable for lead screw drives with high helix threads for quick adjustment of small loads. The zero-backlash lead screw nut is available in six new dimensions.

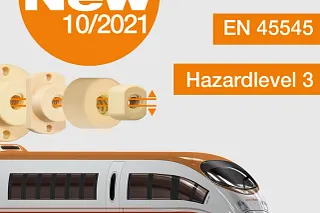

2021

iglidur® J350 material for the rail industry

Certified according to fire standard EN45545 Hazard Level 3

▲ Tech up:

Complies with EN45545 Hazard Level 3

For use in rail vehicles without additional documentation

▼ Cost down:

Cost advantages compared to metallic solutions

Suitability for hazard class HL 3

Predictable service life

Our J350 nuts can now be certified according to fire standard EN45545 Hazard Level 3. We therefore offer a large range of dimensions especially for the use in rail vehicles. They are tested according to the requirement set R24, for components up to 500 grams.

The new dimensions of the dryspin® lead screw technology

High efficiency and self-lubricating

▲ Tech up:

Up to 30% longer service life due to thread asymmetry

Low-noise operation due to rounded tooth geometry

▼ Reduce costs:

100% lubrication and maintenance-free

Up to 50.9% more cost-effective compared to metallic

lead screw nuts

Our plastic lead screw nuts are now available in two new dryspin high helix thread pitches:

► DS6.35x6.35 RH

► DS8x40 RH

The new lead screw nut dimensions

The dryspin® high helix thread technology

▲ Tech up:

Efficiency up to 82%

Low noise and low-vibration operation

▼ Cost down:

100% lubrication and maintenance-free

Up to 50.9% more cost-effective than metallic lead screw nuts

Our designs:

► Cylindrical lead screw nuts

► Flanged lead screw nuts

► Cylindrical injection-moulded nuts

► Injection-moulded nuts with flange

► All types are also available with spanner flat

Six new dimensions

Expansion of the dryspin® lead screw product range

▲ Tech up:

Up to 30% longer service life than conventional lead screws

Low-noise and low-vibration operation due to rounded tooth geometry

▼ Cost down:

Online tool for individual lead screw configuration

Live price display

■ Proof:

Service life can be calculated online

Tested: up to 25% less wear than conventional lead screws

Reduce time spent on design and optimise the procurement process for your lead screw technology.

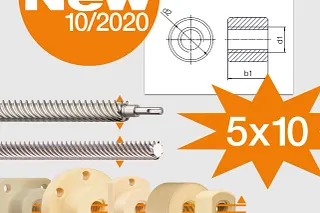

2020

New dryspin® lead screw size 5x10

As an alternative to trapezoidal thread

▲ Tech up:

Smoother and quieter operation at high speeds

Quiet and vibration-free operation

▼ Cost down:

Injection moulding for cost-effective manufacturing

Maintenance-free due to self-lubricating lead screw nuts

Our designs:

► Cylindrical lead screw nuts

► Flanged lead screw nuts

► Cylindrical injection-moulded nuts

► Injection-moulded nuts with flange

► All types are also available with spanner flat

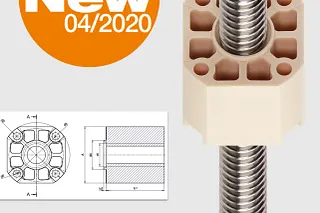

The new type of the series DST-JGRM

Robust and with conventional connection sizes

▲ Tech up:

new design for safe and easy threaded connecting

Connection sizes identical with generally available ball screws

▼ Cost down:

cost-effective and optimised injection-moulded design

Variable design for all Ø14/16 and 18/20 lead screws

■ Proof:

service life predictable online

● Sustainability:

low weight and inertia due to polymer

Long-lasting due to patented thread asymmetry

The new thread sizes

Expand the dryspin® high helix thread range

▲ Tech up:

up to 2.5 times greater efficiency due to optimum flange angle

Completely lubrication-free and maintenance-free

Up to 25% less wear

▼ Cost down:

cost-effective alternative to ball-type linear drives

Service life calculable online

The new dimensions:

► DS6.35x2.54 LH

► DS12.7x12.7

► DS10x3

► DS16x10

► DS20x5