Change Language :

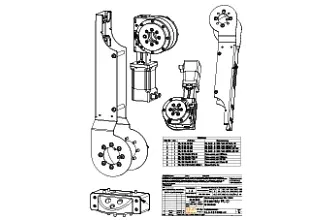

Buy - a complete robot arm (electro-mechanical)

robolink® robot arms are ideal for implementing fast and cost-effective process automation. You can choose from a range of models that are delivered pre-assembled and can be supplemented by an suitable CPR control system. Thanks to the modular kit system, even fully configured articulated arms can be subsequently adapted to changing process conditions by extending or shortening them.

Overview of the various robolink® models

robolink® D robot arms are available in various sizes and with different numbers of high-performance plastic joints. Depending on the application area, e.g. spray water or moisture, special drive motors can be installed for the joints.

robolink® robot arm in use

Data sheets of complete robot arms

Do you need further information and technical data? Take a look at our data sheets to get a better overview.

PDF

Free CAD download

The CAD data of the individual robolink® components, as well as the fully configured articulated arms, can be downloaded free of charge from igus® in various formats and for different CAD systems.

Go to the CAD download centreWould you rather have a self-configured robolink® system?

At igus® you also have the choice to configure a robolink® articulated arm according to your requirements, or to buy components individually. In addition, our components can be combined with your own components, tools and control systems, as well as those made by other manufacturers. This allows robolink® to be customized to suit your individual application in order to design an optimal automation solution.