Change Language :

"Intelligent rebel" - smart plastics now also in the igus ReBeL® service robot

Full transparency during operation for predictive maintenance thanks to smart sensor technology in the igus cobot

Tech up

- Increase machine availability and maximum service life

- Smart application monitoring by means of reading out sensor and kinematics data

- Dashboard connection in a local or external network, connection to PLC and system monitor

Cost down

- Elimination of unplanned downtime or machine failures

- Reduce maintenance costs through early warnings

- Implement condition-based maintenance

Proof

- Tested in the Low-Cost Automation laboratory

- Proven in over 2,500 successful customer projects with the integrated condition monitoring of smart plastics

Sustainability

- Unplanned service deployments can be prevented - eliminating 100km of travel saves about 3.6kg of CO²

- Lightweight components

Smart machine data acquisition forms the basis for predictive maintenance concepts

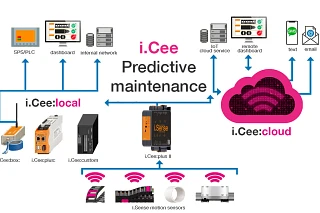

Since the i.Sense Wonderbox is part of the smart plastics i.Sense condition monitoring system, all of its data can also be evaluated in the i.Cee control cabinet module. These data can then be used to digitally control the system's alarm and escalation management.

The i.Cee module can be integrated into predictive maintenance concepts in a number of ways, from preventive service management, which schedules regular maintenance depending on use, to location-independent fault management, which immediately reports any unforeseen change via various mobile channels. All information is collated in a modern dashboard, online or offline in the local network, depending on the customer's requirements.

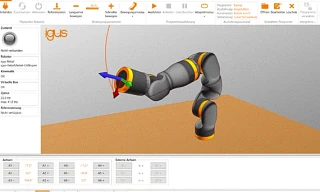

Program the ReBeL and test the application before purchase, free of charge

The new ReBeL robot needs no switch cabinet and is compatible to the igus Robot Control system. Starting right away, you can program and test your individual service robotics application before purchase. The user-friendly software is ideal for beginning programmers.

Just download the free igus Robot Control software. You can start right away with pre-programmed projects for various kinematic elements such as the ReBeL!