Change Language :

... intelligent linear guide ...

... intelligent linear guide ...

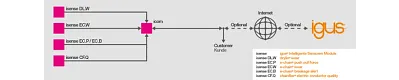

With smart DryLin®, predictive maintenance is a reality. The intelligent linear guide autonomously monitors its use. If isense DL.W (intelligentsensor module) recognizes that a failure due to wearis likely, the operator is automatically informed. Machine availability rises while maintenance costs decrease.

For the world's largest construction kit for linearguides with gliding plastic components, there arealready numerous configurations for calculatingservice life. The data for the calculation come fromthe igus® test laboratory. In an area of more than 29,000 sq ft, approx.15,000 tests with bearings are performed every year. The results are incorporated into the igus® database, thus formingthe basis for service life calculation andcontinuous improvement of the products. With its new smart plastics,igus® is now taking the next steps for even more protectionagainst sudden, unexpected failures.

Cost reduction thanks to:

Predictable maintenance

Prevention of unplanned down-times

Optimal machine availability

Delivery

from June

More information: