Change Language :

Significantly reduce maintenance costs with igus® predictive maintenance | i.Cee

Prevent unplanned downtime through smart plastics

In automotive production, the conveyor belt never stops. Collaborating robot arms for assembly and welding work are in continuous use, as are all of the components that supply them with energy and data. It is in these environments that intelligent concepts in the style of predictive maintenance make the most sense. Whether a new project for Industry 4.0 or efficiency-driven retrofitting - our universal modular smart plastics solutions are can be individually adapted to any system.

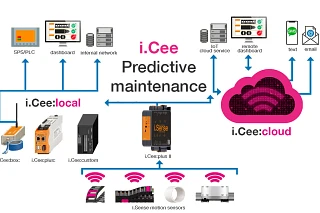

Different production areas... smartly networked...

Types of Smart Plastic Solutions

You determine the route & access of data transfers

i.Cee:local

Your data never leaves your corporate network, since the i.Cee software communicates only within the networks you want it to. The options range from an e-chain® within a single machine to a machine park and your own output interface.

i.Cee:cloud

This online solution has two options. In the first, your data is transferred directly to the cloud, where it is made available in a protected area that can be accessed with a browser dashboard. In the second, the data go to an intermediate location on the i.Cee.net: a data concentrator allowing you to stop or adjust data exchange in the cloud.

i.Cee LIVE Dashboard Demo!

The i.Cee Dashboard visualizes all information and movement data of our smart trade show machine online and in real-time at the igus® virtual-real trade show stand in Cologne.

i.Sense automotive use cases

Download the smart plastics brochure

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert