Change Language :

E-Z triflex R application examples & assembly videos

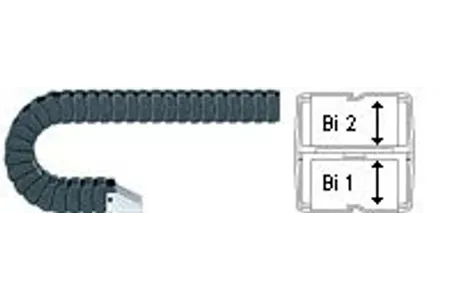

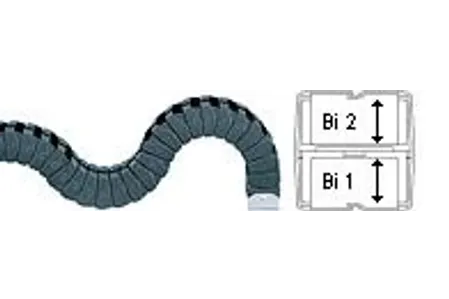

The triflex® series has been developed to safely guide cables during a 3D movement. In this case, the flexibility of a hose is combined with the stability of an e-chain® cable carrier with a fixed, defined radius. With E-Z triflex® the installation of cables and tubes is child's play. The cables can be inserted in the e-chain® from top or bottom through the flexible tongues This unique modular design enables very complex movements. As example: Combination of chain links moving in single, double and triple axes in an e-chain®.

This modular joint system is especially suited for:

- Three-axis movements of machines

- For simple robotic applications

- Quick installation of cables with "easy" system

- Simple filling from both sides

- Where rectangular shapes are required

- Combination of different bending radii and moving directions

- Shortening or lengthening possible at "any point"

- KMA mounting brackets with integrated strain relief

Typical industrial sectors and applications

- Machine tools

- Robotics

- Handling equipment

- Material handling system

- Plastics industry

- Construction machinery

- Vehicle manufacturing

- General mechanical engineering

- Medical

- Equipment

- Office furniture

Application examples

Applications in various industrial sectors and in the igus® test laboratory.

triflex® applicationsContact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert