Change Language :

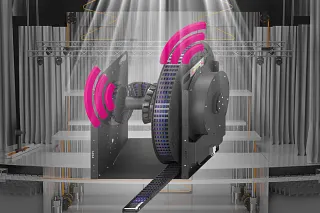

e-spool for stage and theatre rigging

New stage rigging and theatre rigging technology

Certified for stage and event technology according to DIN EN 17206 and DGUV principle 315-

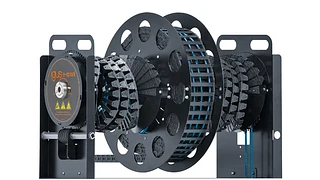

Safely guide many different cables in a confined space with e-spool. e-spool uniquely combines two different energy supply systems: one standard energy chain is guided by a roller, providing the correct length and tension of the energy supply system through an integrated spring. In the home position, the energy chain is completely rolled up to save space. The twisterband connects the roller with the shaft end block, serving as an interface to the supply side cables.

Tech up

- Different media types and sizes safely and reliably guided in one system

- No slip ring necessary

- Layout can also be changed or expanded after assembly

Cost down

- No slip ring, low maintenance

- Price reduced by up to 50% compared to previous e-spool® solutions

Proof

- Tested in the igus laboratory

- Individually projected applications

Sustainability

- Individual engineering and tests are no longer necessary

- Optimized manufacturing process through standardized parts

Optimizations for stage and theatre rigging applications

- Possibility of various sensor monitoring systems

- ø6mm steel cable in accordance with DIN 12348-4 for additional safety

- Mechanical spring force monitoring

- Redundant spring unit

- Positive-locking power transmission with stronger aluminum shaft

Smart rigging hoist with sensor monitoring systems

The e-spool now comes with various sensor monitoring: the spring force of the three springs included is monitored with the help of a load cell sensor. If the force falls below the specified value, the user is prompted to replace the spring. When the specified value is exceeded, there is a blockage that must be removed. The rotation sensor monitoring, which counts the drum rotations and determines the position of the chain and more.

Other e-spool systems

Discover more e-spool systems - the alternative to the cable drum without slip ring. Safely guide many different cables in a confined space with e-spool. e-spool uniquely links two different energy supplies.

White Paper:

Vertical chain hoists in stage rigging

Like every industry, stage technology has its own requirements regarding machine parts and materials. In this white paper, we would like to give you six tips for selecting and designing vertical energy supply systems for stage technology

Entertainment rigging, stage rigging and stage lighting solutions

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert