Change Language :

iglide® J plastic bushings: Material data

Materials tables

| General features | Unit | iglide® J | Test method |

|---|---|---|---|

| Density | g/cm^3 | 1.49 | |

| Color | Yellow | ||

| Max. humidity absorption at 73° F/50% R. H. | Wt.-% | 0.3 | DIN 53495 |

| Max. water absorption | Wt.-% | 1.3 | |

| Coefficient of surface friction, dynamic, against steel | µ | 0.06-0.18 | |

| p x v value, max. (dry) | psi x fpm | 9,700 |

| Mechanical properties | Unit | iglide® J | Test method |

|---|---|---|---|

| Modulus of elasticity | psi | 348,100 | DIN 53457 |

| Tensile strength at 68° F | psi | 10,590 | DIN 53452 |

| Compressive strength | psi | 8,702 | |

| Permissible static surface pressure (68° F) | psi | 5,076 | |

| Shore D hardness | 74 | DIN 53505 |

| Physical and Thermal Properties | Unit | iglide® J | Test method |

|---|---|---|---|

| Max. long-term application temperature | °F | 194 | |

| Max. short-term application temperature | °F | 248 | |

| Min. application temperature | °F | -58 | |

| Thermal conductivity | [W/m x K] | 0.25 | ASTM C 177 |

| Coefficient of thermal expansion (at 73° F) | [K^-1 x 10^-5 ] | 10 | DIN 53752 |

| Electrical Properties | Unit | iglide® J | Test method |

|---|---|---|---|

| Specific volume resistance | Ωcm | > 10^13 | DIN IEC 93 |

| Surface resistance | Ω | > 10^12 | DIN 53482 |

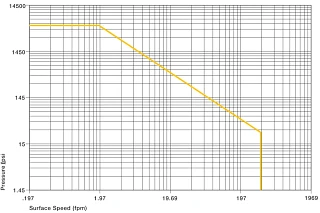

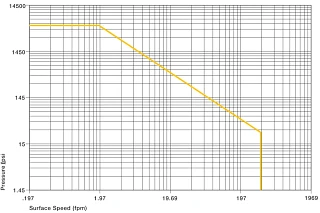

Permissible p x v values

Permissible p x v value for iglide® J plastic bushings running oil free against a steel shaft at 68° F.

iglide® J plastic bushings are characterized by their extremely low coefficient of friction while operating dry and minimal stick-slip effect.

Compressive Strength

With a maximum recommended surface pressure of 5,075 psi, iglide® J plastic bushings are not suitable for extremely high loads. The graph (left) shows the elastic deformation of iglide® J for radial loads. At the maximum recommended surface pressure of 5,075 psi, the deformation is less than 2.5%.

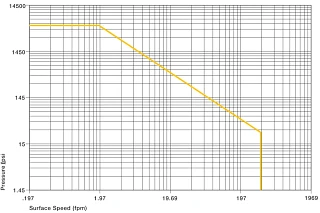

Permissible surface speeds

The low coefficient of friction and extremely low stick-slip tendency of iglide® J plastic bushings are particularly important at very low speeds. However, iglide® J can also be used at speeds over 197 fpm. In both cases, the static friction remains low and stick-slip does not occur.

The maximum values stated in the Table 3.2 can be attained only with minimum pressure loads. The stated values show the speed at which the temperature rises according to friction to the highest permitted value.

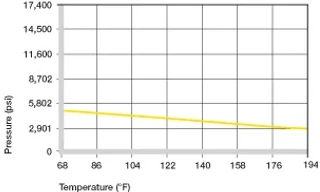

Graph to show that the compressive strength of iglide® J plastic bushings decreases with increasing temperatures. From 176°F onward, the wear drastically increases.

Temperatures

The iglide® J plastic bushings are usable between -58° F and +194° F; the short-term permitted maximum temperature is 248°F.

The diagram shows that the compressive strength of the iglide® J plastic bushings decreases with rising temperatures. From 176° F onward, the wear strongly increases.

The iglide® J plastic bushings are usable between -58° F and +194° F; the short-term permitted maximum temperature is 248°F

| iglide® J | Application temperature |

|---|---|

| Lower | -58°F |

| Upper, long-term | +194°F |

| Upper, short-term | +248°F |

| Additional axial securing | +140°F |

Coefficients of friction for iglide® J with a steel shaft (Shaft finish = 40 rms, 50 HRC)

| iglide® J | Dry | Grease | Oil | Water |

|---|---|---|---|---|

| Coefficients of friction µ | 0.06-0.18 | 0.09 | 0.04 | 0.04 |

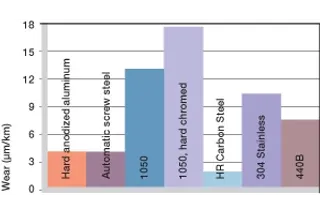

Wear of iglide® J in a rotating application using different shaft materials, p = 108 psi, v = 98 fpm

Shaft materials

The graphs (left) show results obtained from testing different shaft materials with bushings made from our proprietary iglide® J plastic bushings.

If iglide® J plastic bushings are used in rotational applications with loads no greater than 290 psi, several shaft materials are suitable. However, a hard chrome plated shaft generates the lowest amount of wear. When compared to other iglide® materials, iglide® J has very low wear results at low loads with all shaft materials tested.

The wear resistance of iglide® J plastic bushings is exceptional even with increasing loads up to 725 psi. The best shaft partner is 303 stainless steel.

iglide® J wears slightly faster when used in combination with Cold Rolled Steel and HR Carbon Steel shafts in oscillating applications that it does when used with these shafts and rotational movement. For oscillating motion with loads of 290 psi, iglide® J performs best with Cold Rolled Steel shafts.

As the graph (left) shows, the difference between rotating and oscillating movements is most significant for 303 Stainless Steel shafts.

If the shaft material you want to use is not included in this list, please contact us. We'll be happy to help.

Installation tolerances

iglide® J plastic bushings are oversized before pressfit.

After proper installation into a recommended housing bore, the inner diameter adjusts automatically to meet our specified tolerances.

Important tolerances for iglide® J plastic bushings after pressfit, according to ISO 3547-1 for plastic bushings and wrapped bushes

| Diameter d0.03937 [in] | Shaft h9 [in] | iglide® J E10 [in] |

|---|---|---|

| Up to 0.019 | 0-0.009 | +0.00055 + 0.0021 |

| > 0.11 to 0.23 | 0 - 0.0011 | +0.00078 + 0.0026 |

| > 0.23 to 0.39 | 0 - 0.0014 | +0.00098 + 0.0032 |

| > 0.39 to 0.70 | 0 - 0.0016 | +0.00125 + 0.0040 |

| > 0.70 to 1.18 | 0 - 0.0020 | +0.00157 + 0.0048 |

| > 1.1.8 to 1.97 | 0 - 0.0024 | +0.00196 + 0.0059 |

| > 1.97 to 3.15 | 0 - 0.0001 | +0.00236 + 0.0070 |

Chemical resistance

iglide® J plastic bushings are resistant to diluted lyes and very weak acids, as well as to fuels and all types of lubricants. The low moisture absorption also permits their use in wet or damp environments. Plastic bushings made from iglide® J are resistant to common cleaning agents used in the food industry.

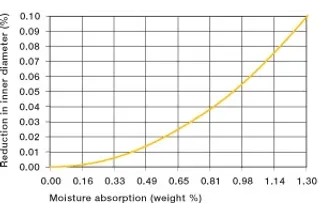

The moisture absorption of iglide® J plastic bushings is 0.3% in standard environments. The saturation limit in water is 1.3%. These values are so low that design changes due to moisture absorption need only be considered in extreme cases.

Legend for the table below:

+ resistant 0 conditionally resistant - not resistant

| Medium | Resistance |

|---|---|

| Alcohol | + |

| Hydrocarbons, chlorinated | + |

| Greases, oils without additives | + |

| Fuels | + |

| Weak acids | 0 to - |

| Strong acids | - |

| Weak alkalines | + |

| Strong alkalines | + to 0 |

Effect of moisture absorption on iglide® J plastic bushings

Radiation resistance

iglide® J plastic bushings are resistant to radiation up to an intensity of 3 x 10² Gy.

UV resistance

iglide® J plastic bushings become discolored under influence of UV radiation. However, the hardness, compressive strength, and wear resistance of the material do not change.

Vacuum

When used in a vacuum environment, the iglide® J plastic bushings release moisture as a vapor. Therefore, only dehumidified bushings made from iglide® J are suitable for vacuum environments. the potentially existent moisture content is degassed.

Electrical properties

iglide® J plastic bushings are electrically insulating.

| Specific volume resistance | Surface resistance |

|---|---|

| > 10^13 Ωcm | > 10^12 Ω |

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert