Change Language :

iglide® A500 - Material data

Materials tables

| General features | Unit | iglide® A500 | Test method |

|---|---|---|---|

| Density | g/cm³ | 1.28 | |

| Color | Brown | ||

| Max. humidity absorption at 73° F/50% R. H. | Wt.-% | 0.3 | DIN 53495 |

| Max. water absorption | Wt.-% | 0.5 |

| Mechanical properties | Unit | iglide® A500 | Test method |

|---|---|---|---|

| Bending E-module | psi | 522,000 | DIN 53457 |

| Bending strength at 68° F | psi | 20,300 | DIN 53452 |

| Maximum recommended surface pressure (68° F) | psi | 17,400 | |

| Shore D hardness | 83 | DIN 53505 |

| Physical and thermal properties | Unit | iglide® A500 | Test method |

|---|---|---|---|

| Upper long-term application temperature | °F | 482 | |

| Upper short-term application temperature | °F | 572 | |

| Lower application temperature | °F | -148 |

| Electrical properties | Unit | iglide® A500 | Test method |

|---|---|---|---|

| Specific forward resistance | Ωcm | > 10^14 | DIN IEC 93 |

| Surface resistance | Ω | > 10^13 | DIN 53482 |

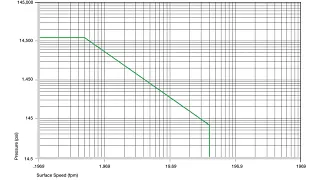

Permitted p x v values

For iglide® A500 plastic bushings with 1 mm wall thickness in dry operation against a steel shaft, at 68° F, installed in a steel housing.

Plastic bushings made of iglide® A500 can be used at high temperatures and are permitted for use in direct contact with foodstuffs (FDA compatible). They exhibit an exceptionally good chemical resistance and are suitable for the heavy-duty use in machinery for the food industry.

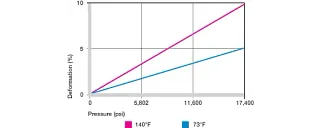

Figure 10.2: Deformation under load and temperatures

Surface pressure

Though iglide® A500 is an extremely soft material, it simultaneously possesses an excellent compressive strength even at high temperatures. Figure 10.2 shows the maximum recommended surface pressure of the bushing dependent on the temperature. This combination of high stability and high flexibility acts very positively during vibrations and edge loads.

As the wear of the bushing rapidly escalates from pressures of 1,450 to 2,901 psi, we recommend a particularly accurate testing of the application above these limits.

Maximum surface speed

Permitted surface speeds

iglide® A500 also permits high surface speeds due to the high temperature resistance. The coefficient of friction rises however by these high rotatary speeds leading to a higher heating up of the bushings. Tests show that plastic bushings made of iglide® A500 are more wear resistant in pivoting motions, and the permitted p x v values are also higher in the pivoting application.

| ftpm | Rotating | Oscillating | Linear |

|---|---|---|---|

| Continuous | 118 | 78 | 196 |

| Short-term | 196 | 137 | 393 |

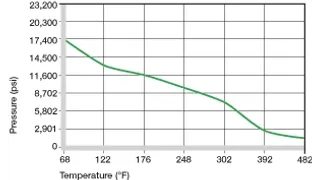

Figure 10.3: Maximum recommended surface pressure dependent on the temperature

Temperatures

The short-term permitted maximum application temperature is 572° F. With increasing temperatures, the compressive strength of iglide® A500 plastic bushings decreases. Fig. 10.3 clarifies this connection. The temperatures prevailing in the bushing system also have an influence on the bushing wear.

Temperature limits

- Lower: -148 °F

- Upper, long-term: + 482 °F

- Upper, short-term: + 572 °F

- Additional axial securing: + 266°F

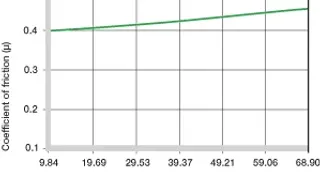

Figure 2.4: Coefficients of friction dependent on the surface speed, p = 108 psi

Friction and wear

The coefficient of friction is dependent on the load that acts on the bushing. In iglide® A500 plastic bushings, the friction coefficient µ initially declines with increasing load. The most favorable coefficient of friction is attained from about 1,450 psi.

Friction and wear also depend to a high degree on the reverse partner. Thus extremely smooth shafts enhance not only the coefficient of friction, but also the bushing wear. Ground surfaces with and average medium roughness range of 16 to 38 rms are the most suitable

Coefficients of friction for iglide® A500 against steel

(Shaft finish = 40 rms, 50 HRC)

- Dry: 0.10 - 0.40

- Grease: 0.09

- Oil: 0.04

- Water: 0.04

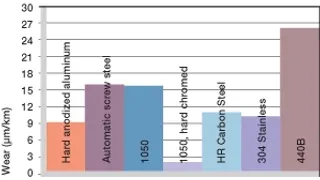

Fig. 2.7: Wear, rotating application with different shaft materials, load p = 108 psi, v = 98 fpm

Shaft materials

The diagrams display a summary of the results of tests with different shaft materials conducted with plastic bushings made of iglide® A500. The combination "iglide® A500/hard-chromed shaft" clearly stands out in rotating application. Up to about 290 psi, the wear of this combination remains largely independent of load.

With regard to oscillating movements against shafts of 1050 steel, the wear resistance is better than that of rotation under the same pressure.

Please contact us in case the shaft material scheduled by you is not included in these figures.

Important tolerances for iglide® A500 plastic bushings according to ISO 3547-1 after the press-fit.

Installation tolerances

iglide® A500 plastic bushings are standard bushings for shafts with h-tolerance (recommended minimum h9).

After the installation in a housing bore with H7 tolerance, the inner diameter of the bushing automatically adjusts to the E10 tolerance.

| Diameter d1 [inch] | Shaft h9 [inch] | iglide® A290 F10 [inch] |

|---|---|---|

| Up to 0.019685 | 0 - 0.00098425 | +0.0002362 + 0.0018110 |

| > 0.1181 to 0.2362 | 0 - 0.0011811 | +0.0003937 + 0.0022835 |

| > 0.2362 to 0.3937 | 0 - 0.00141732 | +0.0005118 + 0.0027953 |

| > 0.3937 to 0.7087 | 0 - 0.00169291 | +0.0006299 + 0.0033858 |

| > 0.7087 to 1.1811 | 0 - 0.00204724 | +0.0007874 + 0.0040945 |

| > 1.1811 to 1.9685 | 0 - 0.00244094 | +0.0011811 + 0.0059055 |

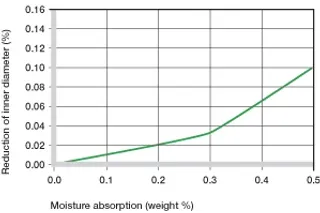

Chemical resistance

iglide® A500 plastic bushings have an excellent resistance to cleaning agents, greases, oils, bases and acids. The moisture absorption of the iglide® A500 plastic bushings is only 0.5% when saturated.

The humidity absorption of iglide® A290 plastic bushings amounts to about 1.7% in standard climatic conditions. The saturation point in water is at 7.3%, a disadvantage which must be accounted for by all means in applications in humid and wet areas.

Please contact us if there is any query about clearance design in humid applications.

| Medium | Resistance |

|---|---|

| Alcohol | + |

| Hydrocarbons, chlorinated | + |

| Greases, oils, without additives | + |

| Fuels | + |

| Weak acids | + |

| Strong acids | + |

| Weak alkaline | + |

| Strong alkaline | + |

Figure 10.10: Influence of moisture absorption of iglide® A500 plastic bushings

Radioactive rays

Plastic bushings made of iglide® A500 figure among the most radiation-resistant bushings in the iglide® product range. The plastic bushings are resistant up to a radioactive intensity of 2 x 105 Gy Higher radiations affect the material and can lead to the loss of important mechanical properties.

UV-resistant

iglide® A500 plastic bushings are largely resistant to UV rays.

Vacuum

The iglide® A500 plastic bushings can be used in vacuum only restrictedly.

Electrical properties

iglide® A500 plastic bushings are electrically insulating.

| Specific volume resistance | > 10^14 Ωcm |

| Surface resistance | > 10^13 Ω |

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert