Change Language :

drylin® N low-profile linear slides

drylin® N low-profile linear slides for small installation spaces

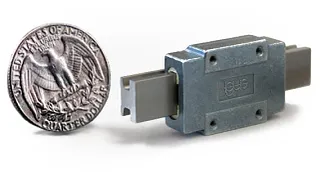

drylin® N low-profile linear slides consist of profile rails and die-cast or plastic carriages. The self-lubricating sliding elements are made of high-performance iglide® polymers. Designed for applications with very limited installation space, their height is as low as 6 to 12 mm (0.24 to 0.47 inches). Pre-loaded versions available to both define the drive force and reduce noise from vibrations.

Applications

drylin® N low-profile rail assemblies are available in various rail heights and widths and are suitable for installation in tight spaces. High-performance materials and an efficient, simple design were used for these low-cost assemblies, suitable for a wide variety of industrial applications.

Browse low-profile linear guide rails, carriages & accessories

drylin® T miniature guide rail assembly

Linear rails with a compact design in 4 installation sizes

drylin® T miniature guide rail assemblies also offer low-profile dimensions at a 40% higher load bearing capacity (up to 315 lbf (1,400 N) than drylin® N assemblies.

Learn more about drylin® N low profile guide rail assemblies

drylin® linear guides expert

A customized drylin® N low-profile guide system for your linear application in only 5 steps.

Tested!

More than 500 drylin® tests annually in the 41,200 sq. ft. test laboratory

FAQ: Frequently Asked Questions

drylin® N guide rails are made of 6060-T66 or 6063-T6 aluminum. They are available in standard clear-anodized or black-anodized options. Custom colors and anodizing after machining is possible depending on volumes. They are also available with or without holes. drylin® N carriages are either all polymer (iglide® J) with brass fastener fittings, or as polymer (iglide® J or J200) guides either clipped or over-molded on a zinc die-cast carriage. Size 27 is also available with a 304SS carriage.

drylin® N rails are stocked standard in North America at either 3650mm (12ft), 2,000mm (6.56ft), or 4,000mm (13.12ft) lengths, depending on the size. These are cut to length to the nearest whole millimeter on a chop saw with a length tolerance of +/- 2mm.

igus® does provide custom machining of drylin® N systems. Custom solutions can be configured using our online configurator tool. If your part cannot be configured with the tool, please send us a drawing for internal review and quoting.

igus® has unique online configuration tools to assist in selecting the best size system for your application needs. The configuration tools use thousands of hours of real-world testing from our test lab in Germany. We provide information including required drive force and safety factors of the system, as well as lifetime expectancy of our liners.

drylin® N is commonly found in lab automation machinery, aircraft and marine interiors, vending machines and kiosks, furniture, and many other industries demanding a small installation space.

There are several series of drylin® telescopic systems including: low-cost all-polymer systems, standard aluminum series (27mm and 60mm wide), prism-guide series for guaranteed precision and holding forces, and a heavy-duty series capable of loads up to 25kg (55lbf). These are most suited for manual applications and require no external lubrication.

drylin® N prism guides and telescopic systems are available in PTFE-free REACH and RoHS options. Contact igus® for more information.

drylin® N is available with pre-loaded parts including a prism rail system (which also comes in Black Anodized Aluminum), carriage clamps, as well as telescopic options.

The dry-running drylin® N preload prism slides are designed to offer a consistent friction force with the removal of clearance. There are several preloads available which guarantee holding forces from 0.5N (0.11lbf) to 16N (3.6lbf) depending on size. This allows precisely controlled adjustment without any stick-slip effect. They are especially ideal for moving monitors, head rests, and other parts into position without the fear of back-driving. Detents are available on certain series.

Standard drylin® N systems are available in profile widths of 17mm, 27mm, 40mm, and 80mm. The assembly heights range from 6mm (size 17), 9.5mm (size 27 and 40), to 12mm (size 80).

Most drylin® N carriages are offered with a clearance hole or a threaded mounting feature (such as a boss) for attachment. drylin® N rails should be aligned using the following guide: Aligning Rails 101.

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert