Change Language :

e-skin® corrugated tube for cleanroom cable management

Guide cables in cleanrooms with e-skin® safely and abrasion-resistant

Corrugated e-skin® tube is available in an enclosed version and a version with chambers that can be opened individually. This flexibility is a unique innovation on the market so far. Furthermore, e-skin has sufficient inherent rigidity and a defined bend radius (55 to 100mm). The oval geometry ensures lateral stability. Short unsupported lengths are possible, even in small installation spaces. Conventional corrugated hoses do not offer this possibility. In addition, the energy supply is very quiet. Its noise level is only 29dB(A), 5dB(A) lower than that of conventional clean cables.

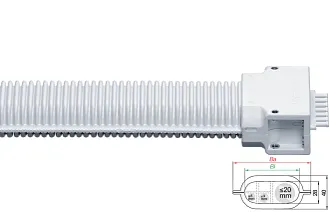

e-skin SK | For unsupported lengths of up to 2.0m and installation space starting at 250mm

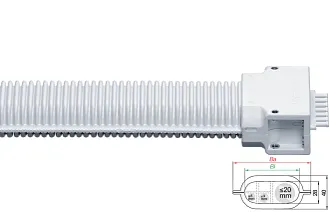

Series SK28

inner height hi : 28 mm

inner width Bi: 68 mm

bend radius R: 055 mm

pitch: 112 mm

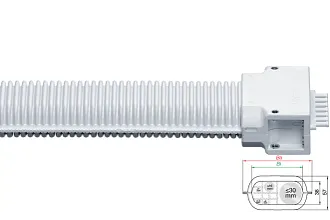

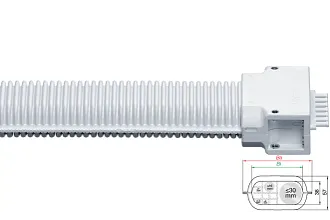

Series SK40

inner height hi : 38 mm

inner width Bi: 85 mm

bend radius R: 100 mm

pitch: 112 mm

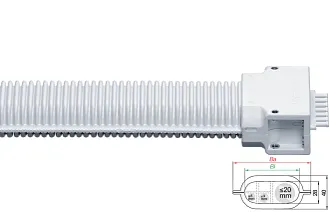

e-skin soft SKS | For unsupported lengths of up to 1.3m and installation space starting at 150mm

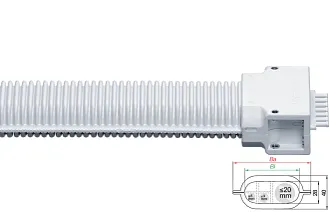

SKS20

inner height hi : 20 mm

inner width Bi: 33 mm

bend radius R: 055 mm

pitch: 112 mm

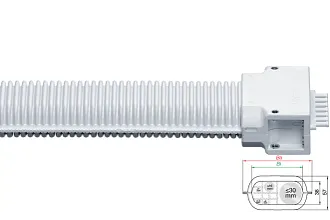

SKS24

inner height hi : 24 mm

inner width Bi: 48 mm

bend radius R: 055 mm

pitch: 112 mm

SKS28

inner height hi : 28 mm

inner width Bi: 68 mm

bend radius R: 055 mm

pitch: 112 mm

SKS40

inner height hi : 38 mm

inner width Bi: 85 mm

bend radius R: 100 mm

pitch: 112 mm

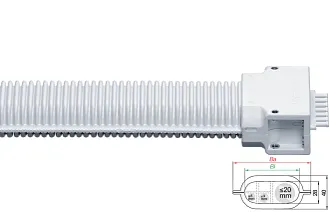

e-skin Hybrid SKY | For unsupported length of up to 1.4m and installation space starting at 200mm

SKY28

inner height hi : 28 mm

inner width Bi: 68 mm

bend radius R: 055 mm

pitch: 112 mm

SKY40

inner height hi : 38 mm

inner width Bi: 85 mm

bend radius R: 100 mm

pitch: 112 mm

Accessories

e-skin® Opener

With the e-skin® opener, the upper and lower shell of the corrugated tube can be opened and closed quickly and easily. This is supplied with the purchase.

Cleanroom-compatible cables

918 types with IPA Class 1 cleanroom classification. 166 types with IPA Class 2 cleanroom classification. Tested and approved with a 4-year guarantee.

Go to the cables

interior separation configurator for the e-skin®

With the interior separation configurator for e-skin® corrugated tubes, you can create filling variants in seconds and configure complete e-skin® corrugated tubes with interior separation and connection elements.

- Simple handling

- Avoidance of filling errors thanks to integrated set of rules

- Automatic creation of a parts list and drawing with dimensions

- Simple enquiry and ordering of the complete corrugated conduit with chainflex® cable and interior separation in the desired configuration

Quality from the igus® cleanroom cleanroom energy standard laboratory

IPA classification

Corrugated tube e-skin® is certified according to the classification ISO class by IPA Fraunhofer Institute:

- e-skin® SK SK28.068.02.1

- e-skin® soft 0.SKS28.068.02.1

- e-skin® hybrid SKY8.068.02.1

Tested at v = 0.5m/s, 1m/s and 2m/s all with ISO Class 1

Tested in the igus® test laboratory for use in the real world

Real-world examples

More information

Frequently Asked Questions

Only unsupported but please contact us and we will find a solution!

Of course, igus® is supplier of chains, cables and readychain systems. Talk to us!

With the new inner separation made of tribo-optimized iglidur® material, the wear can be reduced by up to 80%.

Interior separation configurator for the e-skin®, you can create filling variants in just a few seconds and configure complete e-skin corrugated tubes with interior separation and mounting brackets.

The simple and reclosable opening mechanism enables easy maintenance and inspection of the installed cables.

The e-skin® is a corrugated tube consisting of an upper and lower shell that form a complete enclosure when connected together.

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert