Change Language :

Lubrication-free Motion Plastics for CNC Machines and Machine Tools

Bearings, cable routing, linear, and rotary components built for chips, coolant, and continuous motion

Industry Brochure:

Machine Tools Solutions Magazine

A practical overview of igus solutions used in machine tools, with a focus on reliable energy supply in chip heavy environments. It covers e chain® systems, readychain® pre-assembled options, and smart plastics monitoring concepts that help reduce unplanned downtime.

Browse the Engineer's Toolbox

Machine Variations

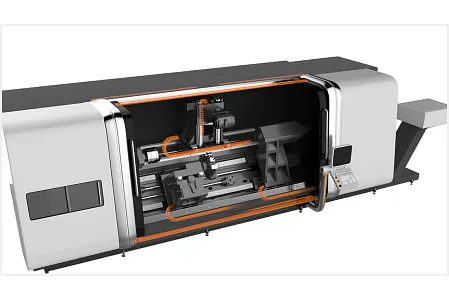

Machining Centers

- Enclosed e-chains shield cables from clips

- High-flex cables ensure reliable motion

- Lubrication-free components minimize maintenance needs

Cutting machines

- Enclosed carriers protect cables from sparks

- Self-lubricating bearings won't clog with dust

- Corrosion-free components endure repeated wet cutting

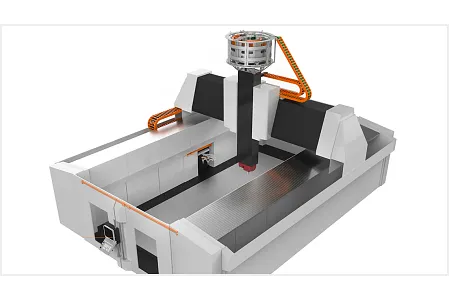

Large machine tools

- Heavy-duty e-chains support long travel

- Sag-resistant chains for long spans

- High reliability under continuous gantry operations

Components for Machine Tool Manufacturing

Browse Relevant Applications

igus supports machine tool builders and retrofit teams with energy supply, continuous flex cables, linear motion, bearings, wear surfaces, and custom plastic parts. Typical touchpoints include cable routing on moving axes, sliding and pivot points that see coolant and chips, and automation add ons like doors, clamps, and small positioners.

Common machine tool categories include machining centers, turning, milling, grinding, plus cutting systems like laser, plasma, and waterjet. igus solutions map well across these platforms because most share the same needs: controlled cable motion, contamination resistance, and lower maintenance motion components.

The biggest repeat offenders are cables and hoses on moving axes, connectors and strain relief, and wear points in doors, guards, and auxiliary mechanisms. A practical approach is to standardize the energy supply (carrier, cable, strain relief) and then address secondary wear points with dry running bearings and low friction liners.

For harsh environments, start with e-chain® cable carriers (including enclosed or chip resistant designs) and pair them with chainflex® continuous flex cables sized for the axis travel and dynamics. This keeps bend radius controlled and reduces kinking, snagging, and premature jacket wear.

Low vibration energy supply matters because vibration can translate into finish issues and process instability in cutting and milling. igus focuses on smoothly operating e-chain® systems and validated designs intended to reduce vibration sources in dynamic motion applications.

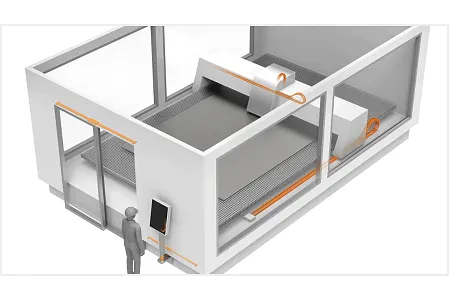

Long travel axes typically require stable guidance for the upper run, predictable sag control, and durable carrier materials. igus supports these designs with machine tool focused e-chain® solutions and long travel support concepts used on large gantry style machining centers.

Preassembled, ready to install harnessing reduces interface count and minimizes termination variability. readychain® systems bundle carrier, cables, and connectors into a delivered assembly to streamline machine build steps and speed commissioning.

Machine tools commonly rely on servo motor cables, encoder cables, and feedback lines that survive continuous motion and high cycle counts. Using application matched chainflex® cables and validated routing inside e-chain® carriers is the baseline for reliable dynamic cabling.

Rotary motion often needs guided cable routing strategies that avoid twisting damage and keep movement controlled. igus covers common approaches including coiled routing concepts and dedicated rotary energy supply solutions for higher rotation demands in machine tools.

Dry running bearing solutions are useful in hinges, pivots, linkages, and auxiliary rotation points where grease is difficult to maintain and contamination is common. igus options include iglide® plain bearings, igubal® spherical bearings for misalignment tolerance, and xiros® ball bearings for light duty rolling functions.

Guard doors and covers need motion components that stay consistent even with chips and coolant exposure. drylin® linear guides and dry running sliding elements can reduce sticking and eliminate relubrication tasks in these secondary axes.

Smaller positioning tasks like sensor moves, light duty adjustments, and access automation often benefit from dryspin® lead screw systems and compact drylin® stages. These are good fits when designers want simple, grease free motion and easier maintenance planning.

Wear shows up in chutes, covers, liners, and machine contact surfaces. tribotape® wear strips and bar and plate stock wear materials provide low friction sliding surfaces that can be cut or machined into replacement wear parts.

When geometry is unique or lead time is tight, teams typically choose 3D printing, CNC machining, or injection molding based on iteration speed and production volume. igus supports this path with custom part options and material focused solutions that align to machine tool wear and contamination needs.

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert