Change Language :

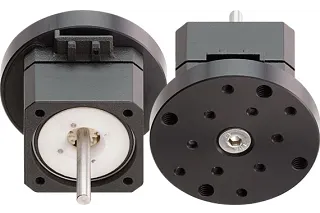

Compact, lightweight design drygear® planetary gearbox in Installation Size 17

Maintenance-free planetary gearbox

The planetary gearbox is impressive because of its very compact and lightweight design. It distributes the load over several gears, so it can transmit high torques. Its high-performance polymer ensures quiet, smooth operation.

- Available transmission: 4:1, 16:1

- Standard motor option: NEMA17 stepper motor

- Max. output torque: 1Nm (4:1), 3Nm (16:1)

- INI for position determination available (optional)

- Direct motor connection or drive shaft possible

- Output via adapter disc or shaft possible