Change Language :

FDA-compliant, Food-safe Parts for Food Packaging

Our FDA-compliant and EU 10/2011 certified polymers are self-lubricating and dry-running, meaning they don’t require external lubricants and eliminate the risk of contamination. They’re also maintenance-free and resistant to corrosion and chemicals. Our polymer materials can be used on all types of shafts – including 300 series stainless steel – offer low moisture absorption rates, and can withstand continuous operating temperatures of up to 482⁰F. Most orders ship within 48 hours directly from our warehouse.

Application Examples

Waffle Baking Machines

- No corrosion due to high humidity

- High-temperature applications without axial safety (T>338°F) due to tempered iglide® plain bearings

- High wear resistance

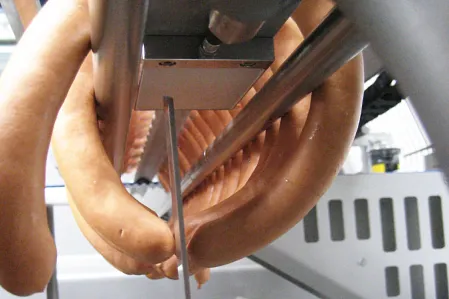

Meat and Fish Processing

- Corrosion resistant even in hot cleaning process

- iglide® X plain bearings as standard solution for "hot" and "cold" applications

- FDA-approved high-temperature solution iglide® A500

Dessert Processing

- Maintenance-free, self lubricating, corrosion-resistant, no damage of stainless steel shafts

- Good chemical resistance against brine / typical detergents (Hydrogen peroxide, bases, peracetic acid)

Browse Food-Safe Parts

Browse the Engineer's Toolbox

Food packaging lines must meet food safety, hygienic design and sanitation requirements in addition to speed and uptime targets. Every component near open product is evaluated for food-contact materials, cleanability and resistance to washdown and CIP cleaning chemicals. Many OEMs now combine stainless steel structures with food-grade, self-lubricating plastic bearings and guides to reduce contamination risk and simplify cleaning.

Grease and oil near open product create a risk of food contamination, recalls and audit issues. Using self-lubricating, dry-running bearings and linear guides removes external lubricants from critical zones, which supports HACCP plans, FDA compliance and hygienic design. Polymer bearings and sliding elements from suppliers like igus can operate without added grease, helping food packagers reduce both maintenance and contamination risk.

FDA-compliant and EU 10/2011-compliant materials are tested so they are safe for food contact and splash zones under defined conditions. For bearings, guides, scrapers and change parts this means the plastic formulation and any additives meet migration limits and documentation requirements. Many food packaging OEMs now standardize on materials that satisfy both FDA and EU 10/2011, so the same motion components can be used on global machines.

Typical motion elements include bearings, linear slides, conveyor rollers, gears, slewing rings and cable systems on form fill seal, flow wrap, tray seal and cartoning lines. These parts guide film, pouches, trays and cartons through the process. Increasingly, designers combine stainless steel shafts with food-grade polymer bearings, self aligning joints and low friction liners to reduce lubrication and corrosion problems.

Frequent washdown, foam cleaning and CIP expose parts to water, caustic and acidic chemicals and temperature swings. Components must be corrosion resistant, easy to rinse and compatible with cleaning agents to avoid swelling, cracking or seizing. This drives use of stainless steel hardware and grease free plastic bearings and liners formulated for washdown food packaging environments.

Hygienic design helps prevent product buildup, bacterial growth and cross contamination around moving parts. Motion components should have smooth surfaces, minimal crevices and no exposed grease that can trap residues. Lubrication free plastic bearings, open linear slides and rounded housings support GMP and hygienic design guidelines in food packaging plants.

Food packaging lines use visual inspection, metal detection and X ray to catch foreign bodies before shipping. To support this, many components near product are made from blue or metal detectable plastics, so fragments stand out or can be picked up by detectors. Detectable bearings, bushings and change parts are now common in high risk zones over open product.

Plastic bearings and rollers appear on conveyors, transfer points, labelers, diverters, flap mechanisms and adjustment slides where moisture and cleaners are present. In these areas, food-grade polymer bushings, plastic ball bearings and wear strips provide a corrosion resistant, low friction, maintenance free alternative to greased metal components and help keep lines cleaner and quieter.

Plants often standardize on a small set of food-grade materials, bearing families and bar or plate stock that are approved by quality and food safety teams. Using the same FDA / EU 10/2011 materials and blue or detectable plastics for scrapers, guides and bushings simplifies audits and spare-parts management across multiple packaging lines.

Custom stars, pockets, funnels and guides for new products are typically made from food safe plastics or stainless steel using CNC machining or industrial 3D printing with food-grade materials. Many suppliers, including igus, offer on demand manufacturing and semi finished food-grade stock so engineers can obtain compliant change parts quickly while meeting food packaging hygiene and regulatory requirements.

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert