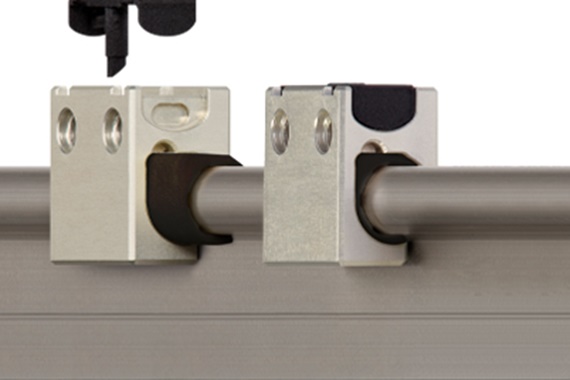

longer service life

lower procurement and assembly times

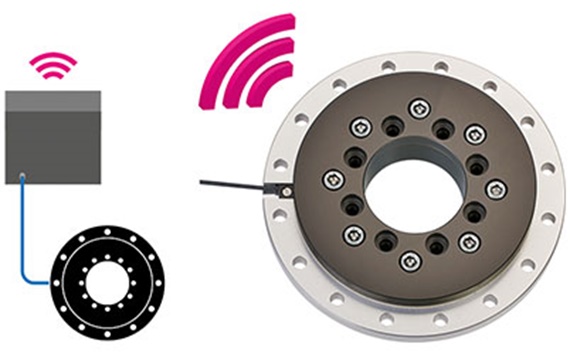

integrated intelligence (smart plastics)

better properties than metal

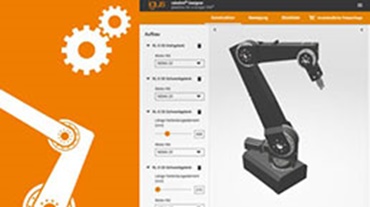

Individually configurable robotic arm from the first axis up to the tool

Simulate movement of the robotic arm with the help of inverse kinematics or means of the individual joints

Option of direct request and easy transfer to shopping cart, output of parts list

Calculation of the expected service life of over 19 iglide® materials

Conditions such as loads, temperature, chemicals, etc. can be incorporated

Direct inquiry option

Customised configuration of the lead screw

Output of a 2D drawing for quick inspection

Production drawing in minutes, a quotation within the shortest time