Change Language :

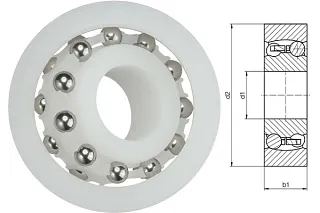

xiros® self-aligning ball bearings

Corrosion-resistant xiros® self-aligning ball bearings

With our first self-aligning ball bearing according to the standard DIN 630 made of the high-performance plastic xiros B180, you can not only compensate for misalignment on shafts of up to 4° but also absorb higher loads due to the balls being arranged in a double row. The self-aligning ball bearing is initially available in four installation sizes for average shaft diameters of 8, 10, 12 and 20mm. Ideal for applications in general mechnaical engineering.

Benefits:

- Compensates for misalignments

- Corrosion-resistant

- Lightweight

- Dry-running

Facts about self-aligning ball bearings

Due to the lower degree of oscillation of the rolling elements on the outer ring compared to single-row radial deep groove ball bearings, self-aligning ball bearings can absorb smaller radial loads. How much the swivel bearings can accommodate in an axial direction depends on the respective pressure angle. The raceway of the outer ring has the shape of a hollow ball, as a result of which the inner ring together with the balls can pivot around the center point of the self-aligning ball bearings within certain tolerances during simultaneous rotation. Pivoting is possible without the creation of any additional friction.

How is that possible? This is because the lateral direction of movement of the balls is considerably smaller than the movement along the circumference. A high degree of friction is created, however, if there are pivoting movements under full load and fixed raceway rings are being used. A sliding movement occurs and the balls become locked.

When is a self-aligning ball bearing the right choice for my application?

- When a large pivoting angle is needed

- When machining errors/assembly errors or instances of shaft bending have to be compensated for

- When spindles have to be supported where a small axial wobble plays a role (spherical outer raceway)