- Wear-resistant: min. 30 to 60 times longer service life compared to conventional 3D printing resins

- High strength and rigidity (flexural strength 90MPa)

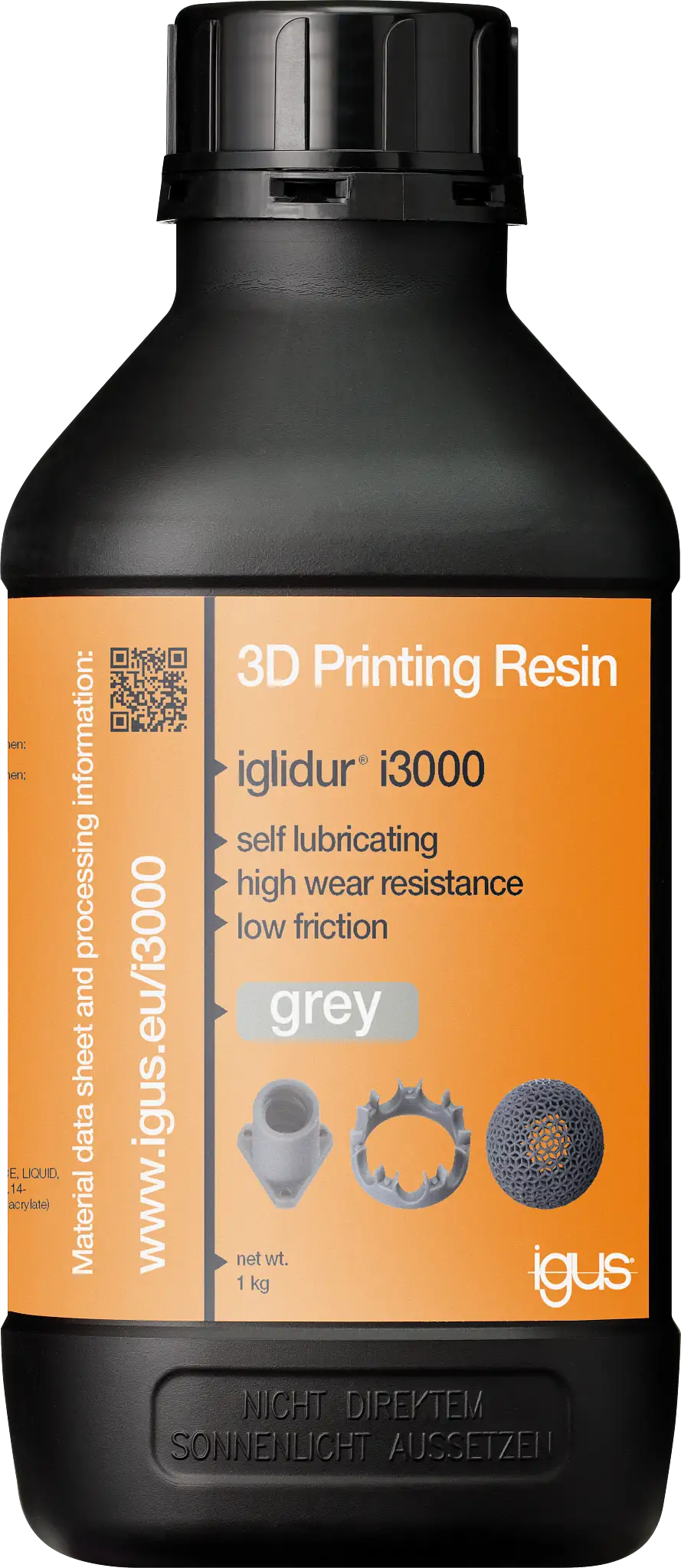

- Self-lubricating and low maintenance

- High level of detail: resolution down to 35μm

- Easy to process on DLP and LCD printers

Material profile for different 3D printers, e.g. Asiga and Formlabs, available for download