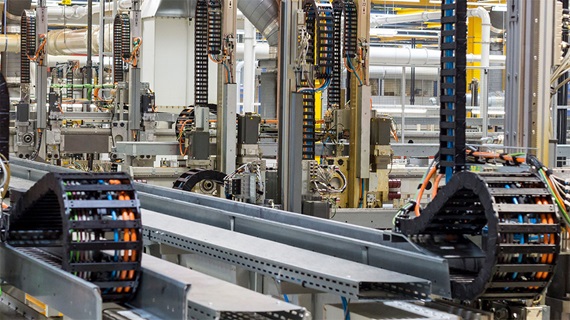

Site: engine plant in Austria. Application: indoor linear robot for the automated handling of engine blocks. At the engine plant in Austria, the largest and most important engine plant of a major German car manufacturer, an engine comes off the assembly lines every 14 seconds on average - at peak times more than 6,000 engines are produced each working day. This extremely high output can only be achieved with a high degree of automation and with extremely reliable components. The goal of the operators is to always avoid failures and system downtimes if possible. These high standards were therefore also set for the energy supply system of the indoor gantry. In fact, this later has to work continuously in 18 to 19 shifts per week with high dynamics. Future energy supplies can quickly reach cycles in the millions.

Industry: Automotive

Which smart plastics technology is used?

P4.1 roller chain, i.Sense EC.B, chainflex cables

Why is it used?

Increase in plant safety and availability; complete project implementation from a single source; smart early warning system.

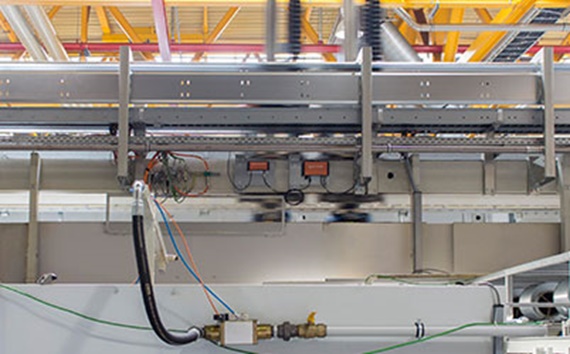

Industry: Crane

Which smart plastics technology is used?

i.Sense EC.P for permanent monitoring of the system

Why is it used?

The system includes intelligent sensors for monitoring the pull/push forces, which can be used for an emergency shutdown in the event of increased forces.

Industry: Crane

Which smart plastics technology is used?

Roller energy chains with the iSense EC.P pull/push force detectio.

Why is it used?

To avoid system damage and failures through preventive maintenance or remote intervention.

Industry: Crane

Which smart plastics technology is used?

EC.P for push/pull forces, EC.B for chain breaks, CF.P for measuring tensile force on cables, EC.M for movement data and EC.W for measuring abrasion and a predictive maintenance system.

Why is it used?

The customer now has full control, overview and safety.

Industry: Automotive

Industry: Transport

Industry: Packaging

Which smart plastics technology is used?

E4.1L e-chains® and chainflex® cables pre-assembled as a readychain, CF.Q isense sensors, Module Connect connector.

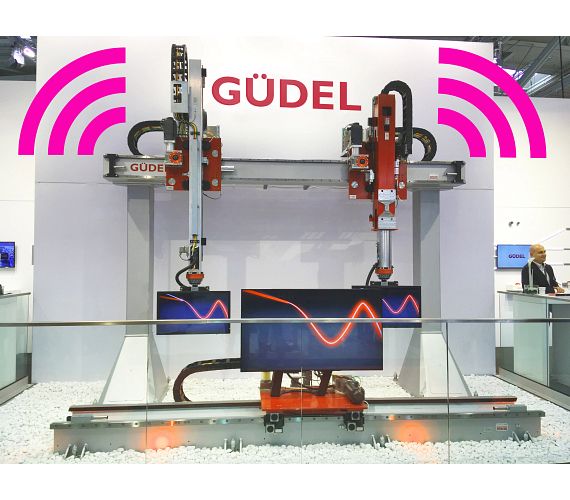

Industry: Robotics

Which smart plastics technology is used?

EC.M sensor for motion data and EC.W sensor for the measurement of abrasion along the energy chain

Industry: Mining

Which smart plastics technology is used?

EC. P System as a cleaning or maintenance reminder.

Why is it used?

The heavy dust arising during the movement of bauxite is an enormous stress, especially for moving machine components.

Industry: Wastewater and sewage treatment plants

Industry: Agriculture