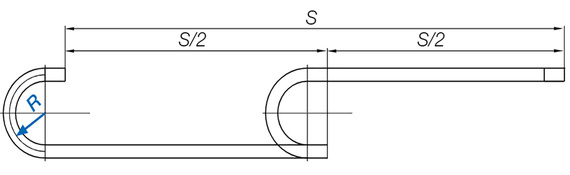

If the fixed end of an; e-chain® cable carrier is located in the center of the travel, the cable carrier's length, "LK", is calculated by using half the length of travel and adding the value "K" for the bending radius. Placing the Fixed End in the center of the travel is the most cost-effective solution because it requires the shortest cable carrier, cables and hoses.

For unsupported applications, the energy chain's upper run moves parallel to the lower run across the entire horizontal travel.

| The fixed end in the center of the travel is always the most cost-effective solution |

Fill weight - Weight of all cables and hoses, including contents (for media hoses) within the e-chain®. Please consult an igus® e-chain® expert if you need help finding a suitable e-chain® cable carrier for your fill weight and travel distance. |

| Abbreviations | Meaning | Unit |

|---|---|---|

| LK | Energy chain length | [mm] |

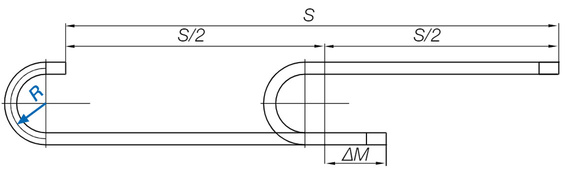

| S/2 | Half length of travel | [mm] |

| K | Add-on for bend radius (K is taken from the data tables of the individual series) | [mm] |

| ∆M | Deviation of the centre point | [mm] |

| R | Bend radius | [mm] |

| Abbreviations | Meaning | Unit |

|---|---|---|

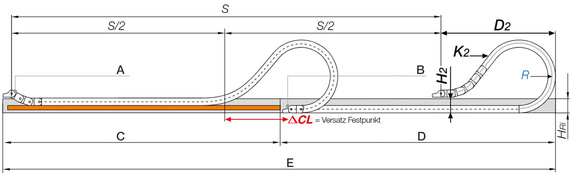

| LK | Energy chain length | [mm] |

| S/2 | Half length of travel | [mm] |

| K2 | Add-on for bend radius if the mounting point height is lowered | [mm] |

| ∆CL | Offset fixed end | [mm] |

| R | Bend radius | [mm] |

| D2 | Over length for long travels gliding | [mm] |

| H2 | Installation height with lowered mounting | [mm] |

| HRi | Inner trough height | [mm] |

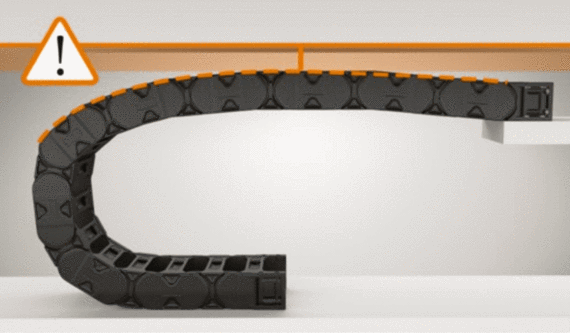

"Camber" is the curve of the upper run along its unsupported length. All igus® e-chains® are manufactured with camber, special "no camber" (NC) energy chains are available upon request. The camber allows for longer unsupported lengths and increases service life and operating safety. In the Installation Dimensions section of each respective energy chain description, you will find the measurement HF, which specifies the necessary clearance height, taking the camber into account. The camber allows for longer unsupported lengths and increases service life and operating safety. Upon request, we can deliver e-chains® without camber for restricted space applications - however, these "no camber" chains do not have the same load-bearing capacity.

| Abbreviations | Meaning | Unit |

|---|---|---|

| H | Nominal clearance height | [mm] |

| HF | Required clearance height | [mm] |

Advantages of camber:

|

We can assist you with a turnkey, fully assembled solutions or answer any questions you may have with a custom project.

Dan Thompson

Product Manager - North America

(800) 521-2747