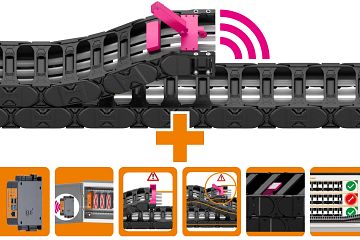

i.Sense EC.PSensors installed on the e-chain® moving end side continuously measure the push/pull force required for the movement. They then transmit it via cable to a top-hat rail DIN module installed in the switch cabinet. Most failures are preceded by an increase in the force applied, e.g. due to foreign bodies, snow/ice, misalignment, or deformed or loose guide troughs. Based on experience gained in the igus laboratory and thousands of applications in the field, the force limits determined for the application are copied onto the module via an SD card before the product is dispatched. If these force limits are exceeded according to correction algorithms, an NC contact is operated to inform the customer's control system, which can then avoid damage by quickly switching the equipment off.

- The EC.P (EC = e-chain P = pull force) sensor is mounted on the (floating) moving end of the e-chain.

- There, it measures pull forces applied to the e-chain.

- If force thresholds are exceeded, the sensor reports the event and, as necessary, switches off the system to prevent expensive damage to the system.

i.Sense EC.P is

already a long-standing standard on cranes in container logistics. Other typical applications besides cranes are in sewage treatment plants or automotive manufacturing.

i.Sense:modul IIThe i.Sense evaluation unit is designed for simple module installation on DIN top-hat rails and allows fast integration into the existing plant control system via normally closed contacts (24 V DC power supply). All sensor data are evaluated based on igus® algorithms and accordingly inform the plant control system instantly in the event of emerging mechanical faults.

* Prices for products with chainflex cable do not include copper surcharge.