Inquiry / Contact

igus® inc.

| General features | Unit | iglide®K | Testing method |

| Density | g/cm³ | 1.52 | |

| Color | yellow-beige | ||

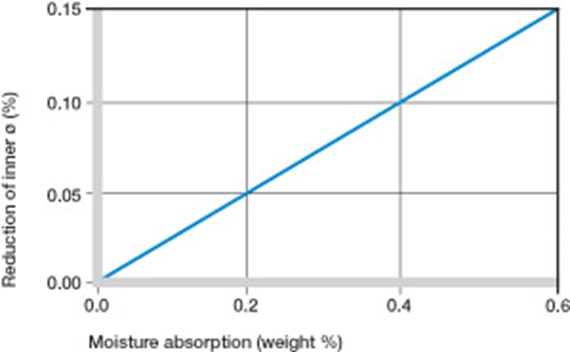

| Max. moisture absorption at 73°F/50% R. H. | Wt.-% | 0.1 | DIN 53495 |

| Max. moisture absorption | Wt.-% | 0.6 | |

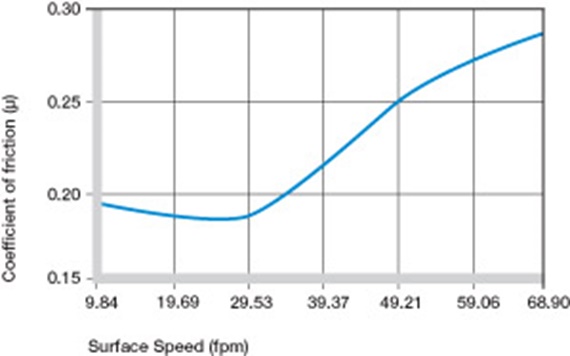

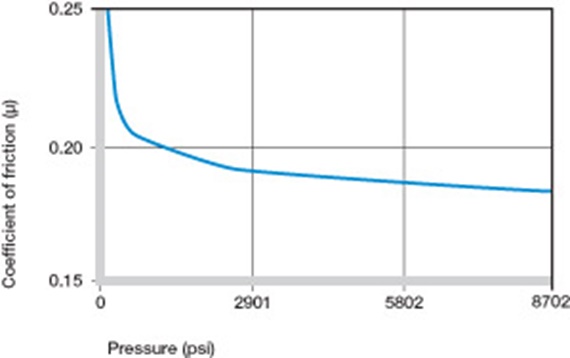

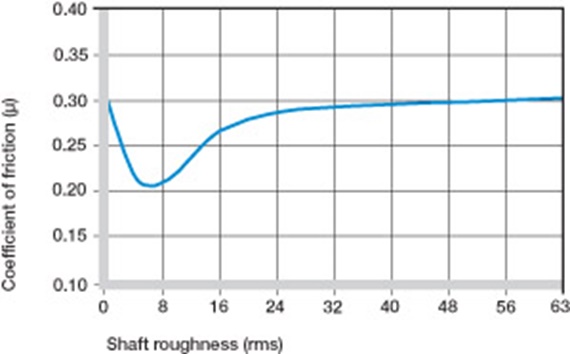

| Coefficient of surface friction, dynamic, against steel | µ | 0.06 - 0.20 | |

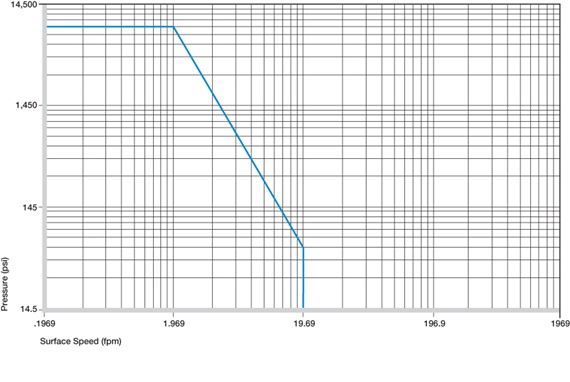

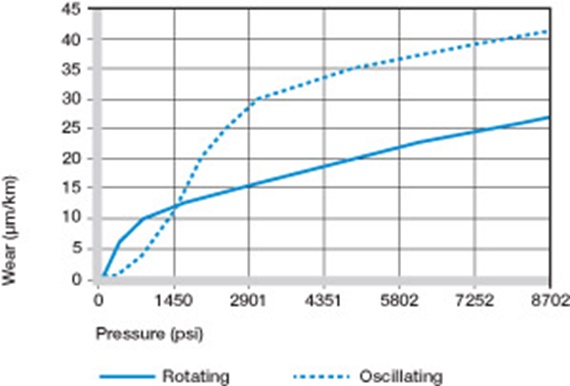

| P x v value, max. (dry) | psi x fpm | 8,600 | |

|

Mechanical properties |

|||

| Modulus of elasticity | psi | 507,600 | DIN 53457 |

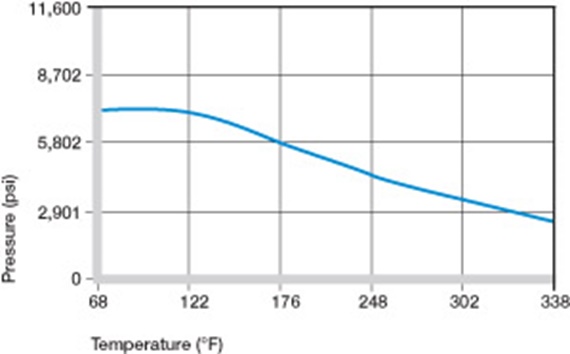

| Tensile strength at 68° F | psi | 11,600 | DIN 53452 |

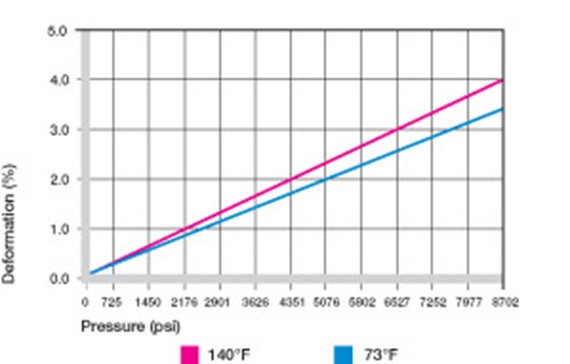

| Compressive strength | psi | 8,702 | |

| Maximum recommended surface pressure (68° F) | psi | 8,702 | |

| Shore D hardness | 72 | DIN 53505 | |

|

Physical and thermal properties |

|||

| Upper long-term application temperature | °F | 338 | |

| Upper short-term application temperature | °F | 464 | |

| Lower application temperature | °F | -40 | |

| Thermal conductivity | W/m x K | 0.25 | ASTM C 177 |

| Coefficient of thermal expansion (at 73° F) | K-1 x 10-5 | 3 | DIN 53752 |

|

Electrical properties |

|||

| Specific volume resistance | Ωcm | > 1012 | DIN IEC 93 |

| Surface resistance | Ω | > 1012 | DIN 53482 |

| fpm | Rotary | Oscillating | Linear |

| Constant | 197 | 137 | 591 |

| Short-term | 393 | 275 | 787 |

| iglide® K | Application temperature |

| Lower | -40°F |

| Upper, long-term | +338°F |

| Upper, short-term | +464 °F |

| Additional axial securing | +158 °F |

| iglide® K | Dry | Grease | Oil | Water |

| Coefficients of friction µ | 0.06-0.21 | 0.09 | 0.04 | 0.04 |

| Medium | Resistance |

| Alcohols | + to 0 |

| Hydrocarbons, chlorinated | + |

| Greases, oils, without additives | + |

| Fuels | + |

| Weak acids | 0 to - |

| Strong acids | - |

| Weak alkaline | + |

| Strong alkaline | 0 |

| Specific volume resistance | > 1012 Ωcm |

| Surface resistance | > 1012 Ω |

| Diameter

d1 [mm] | Shaft h9

[mm] | iglide® K

E10 [mm] | Housing H7

[mm] |

| 0 to 3 | 0 - 0,036 | +0,014 +0,054 | 0 +0,010 |

| > 3 bis 6 | 0 - 0,030 | +0,020 +0,068 | 0 +0,012 |

| > 6 to 10 | 0 - 0,043 | +0,025 +0,083 | 0 +0,015 |

| > 10 to 18 | 0 - 0,043 | +0,032 +0,102 | 0 +0,018 |

| > 18 to 30 | 0 - 0,052 | +0,040 +0,124 | 0 +0,021 |

| > 30 to 50 | 0 - 0,062 | +0,050 +0,150 | 0 +0,025 |

| > 50 to 80 | 0 - 0,074 | +0,060 +0,180 | 0 +0,030 |

| > 80 to 120 | 0 - 0,087 | +0,072 +0,212 | 0 +0,035 |

| > 120 bis 180 | 0 - 0,100 | +0,085 +0,245 | 0 +0,040 |

Table 07: Important tolerances for iglide® K plastic bushings according to ISO 3547-1 after the press-in