Change Language :

iglide® Plastic Bushings - p x v value and lubrication

Table 1.3: Heat conductivity values of shaft or housing materials

| Material | Thermal Conductivity [W/m x k] |

|---|---|

| Steel | 46 |

| Aluminium | 204 |

| Cast iron | 58 |

| V2A | 16 |

| Ceramic | 1,4 |

| Plastic | 0,24 |

Permitted p x v value

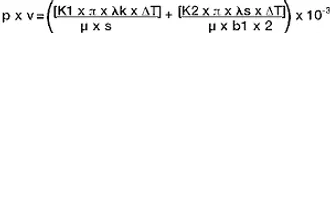

For plastic bushings, the product is given a new value depending on the specific load (p) and the surface speed (v). The p x v value can be considered a measure of the frictional heat and can be used as an analytical tool to answer questions concerning the proper application of a plastic bushing. For this purpose, the actual p x v value is a function of the shaft material of the ambient temperature and the operating time.

Present is:

- K1, K2: Constant for heat dissipation, where K1=0.5, K2=0.042

- s: Plastic bushing wall thickness (inch)

- b1: Plastic bushing length (inch)

- μ: Coefficient of friction

- λs: Heat conductivity of the shaft

- λk: Heat conductivity of the plastic bushing

- ΔT: (Ta-Tu)

- Tu: Ambient temperature

- Ta: Max. ambient temperature

Correction factor

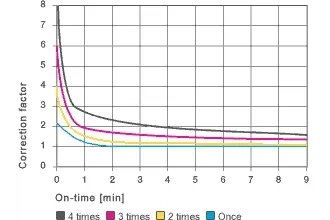

The tolerated p x v value can be increased in intermittent operation if the plastic bushing temperature never reaches its maximum limit because of the short operating times. Tests have shown that this is true for operating times below 10 minutes. An important qualifier here is the ratio of the operating time and pause intervals. Long pauses make a greater contribution to re-cooling.

The different curves in Figure 1.9 represent different ratios ("3 times" means that the pause lasts 3 times longer than the operating time).

Formula:

Table 1.4: Adjustment of the permitted p x v value through lubrication

| Lubrication | Correction factor |

|---|---|

| Dry operation | 1 |

| In the installation | 1.3 |

| Persistent, fat | 2 |

| Persistent, water | 4 |

| Persistent, oil | 5 |

Additional Technical Information

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert