Change Language :

Hybrid e-chain® cable carrier made of plastic and steel

No rivets, no screws, easy cable change.

Why choose hybrid e-chains vs. standard steel cable carriers?

Hybrid e-chain® advantages

Tech up

- Almost 50% less weight 1

- Longer unsupported length 2

- High tensile strength

- No screws, rivets or bolts that can become loose under vibration

- Robust: steel mounting brackets with attachment options from any side

- Smooth operation due to plastic pin connection

- Wide range of interior separation elements

1 Compared to a pure steel chain of comparable size

2 Compared to a comparable plastic e-chain®

Cost down

Proof

Sustainability

hybrid e-chain® with crossbars every 2nd link, openable from both sides

Series YE.42

Inner height hi: 42mm

Outer height ha: 76mm

Inner width Bi: 100 - 400mm

Outer width Ba: 118 - 418mm

Bend radii R: 100 - 150mm

Pitch: 67mm

Series YE.56

Inner height hi: 56mm

Outer height ha: 90mm

Inner width Bi: 100 - 600mm

Outer width Ba: 124 - 624mm

Bend radii R: 100 - 500mm

Pitch: 91mm

hybrid e-chain® with crossbars every link, openable from both sides

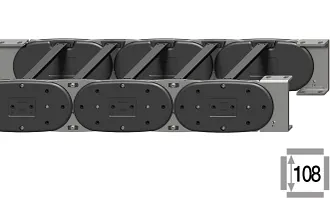

Series YEHD.108

Inner height hi: 108mm

Outer height ha: 146mm

Inner width Bi: 387 - 550mm

Outer width Ba: 435 - 598mm

Bend radii R: 250 - 600mm

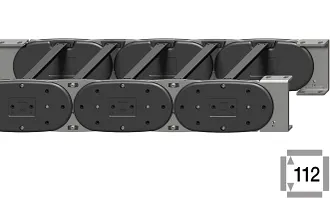

Series YEHD.112

Inner height hi: 112mm

Outer height ha: 146mm

Inner width Bi: 100 - 600mm

Outer width Ba: 148 - 648mm

Bend radii R: 250 - 600mm

hybrid e-tube, openable from both sides, pivoting lid - protection against chips and dirt

iSet YE | Travels: 6 - 18m

Save time and money with our complete hybrid energy chain system. No need shop around for the right accessories. Suitable for construction machinery, cherry pickers, telescopic loaders, construction machinery.

White Paper:

Future-Proof Your Elevated Work Platforms

Discover how innovative energy supply systems are revolutionizing telescopic work platforms and cherry pickers. Learn about hybrid chains that combine the best of steel and plastic, maintenance-free solutions, and IoT-ready components that can reduce downtime and boost reliability.

Learn more about the components in YE.42

Plastic outer side links provide weight reduction and quick assembly.

Steel inner side links provide increased strength and longer unsupported spans.

Ideal strength to weight ratio carrying heavy loads over a long span with compact dimensions and the lowest possible weight.

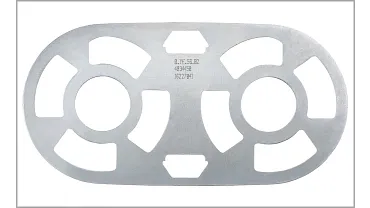

Multiple widths available from 50mm - 400mm inner width. Crossbars can be removed along the inner and outer radius.

Standard interior separation available from the proven igus E4 modular system.

Steel mounting brackets with attachment points from top, bottom, or front.

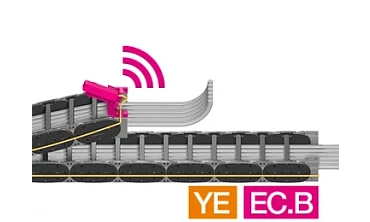

The smart break detection i.Sense EC.B is also now available for the YE(HD) series. This protects your application from unexpected downtimes.

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert