Change Language :

igubal® self-aligning bearings: technical data

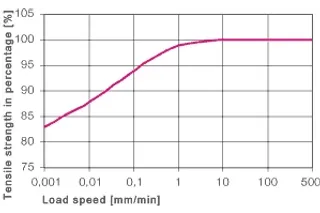

Influence on the tensile strength of igubal® self-aligning bearings at different speeds.

Loads

The load capacity of igubal® self-aligning bearings is high at normal ambient temperatures. igubal® bearings absorb high forces and at the same time weigh only a fifth of traditional metal bearing housings. The excellent dampening properties are based on the fact that the plastic material of the two-part bearing can absorb vibrations differently than steel.

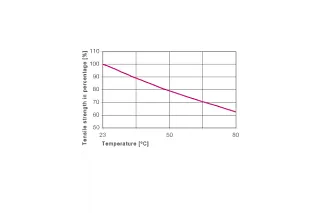

However, plastic-specific properties, such as temperature and behavior under long-term stressing, must be taken into consideration when using igubal® bearings. The load capacity should therefore be checked in a performance test, particularly if they are to be used under continuous high loads and at elevated temperatures.

Effect of the temperature on the maximum tensile strength of igubal® bearings

Coefficients of sliding friction and speed

One important advantage of igubal® bearings is that rapid, rotary movements of a mounted shaft take place directly in the spherical part. The bearings operate in such a way that angular movements take place at the outer diameter, while shaft rotations are supported directly in the inner diameter of the spherical portion. In contrast, with metal rod ends, for example, rotary motion takes place between the race and the spherical bearing. The igubal® bearing design means that rotational surface speeds up to 1.64 ft/s can be achieved.