Change Language :

What does the chainflex® "class"(ification) mean?

For over 20 years, igus® has been providing cables under the chainflex® brand for continuous motion within e-chain® cable carriers. chainflex® cables are uniquely suited to work reliably within e-chains® above all else.

To achieve this, chainflex® cables must meet demanding requirements in all e-chain® applications, such as small bending radii, high cycle frequencies, small installation spaces, exposure to various chemicals, and other dynamic parameters.

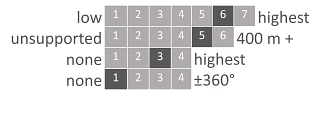

igus® rigorously tests all chainflex® cables at our in-house technical center and test lab. The results of these tests ultimately lead to all cables being given a specific classification. Each "class" is based on the following four criteria: basic requirements, travel length, oil resistance, and torsion.

chainflex® class is composed of:

chainflex® class is composed of:

Basic Requirements 1 to 7

Travel Distance 1 to 6

Ouil Resistance 1 to 4

Torsion 1 to 4

In theory the following classes would be possible: lowest "Class 1.1.1.1", highest "Class 7.6.4.4"

Example: You are looking for a cable which meets the highest mechanical requirements, meets oil resistance requirements in accordance with DIN EN 50363-10-2, travels up to 100m in an unsupported gliding application, and doesn't require any torsional movement. The classification would be as follows:

Basic requirements: 6

Travel distance: 5

Resistance to oil: 3

Torsion: 1

This results in the rating of the cable – "Class 6.5.3.1" in this case – which you can also find in the respective product pages.