Change Language :

iglide® Q2 - Material data

Materials table

| General features | Unit | iglide® Q2 | test method |

|---|---|---|---|

| Density | g/cm3 | 1.46 | |

| Colo | beige-brown | ||

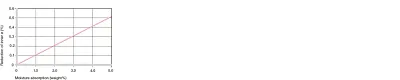

| Max. moisture absorption at 73°F/50% R. H. | Wt.-% | 1.1 | DIN 53495 |

| Max. moisture absorption | Wt.-% | 4.6 | |

| Coefficient of surface friction, dynamic, against steel | µ | 0.22-0.42 | |

| P x v value, max. (dry) | psi x fpm | 19,500 | |

| Mechanical properties | |||

| Modulus of elasticity | psi | 1,214,000 | DIN 53457 |

| Tensile strength at 68° F | psi | 34,810 | DIN 53452 |

| Compressive strength | psi | 18,850 | |

| Maximum recommended surface pressure (68° F) | psi | 17,400 | |

| Shore D-hardness | 80 | DIN 53505 | |

| Physical and thermal properties | |||

| Upper long-term application temperature | °F | 266 | |

| Upper short-term application temperature | °F | 392 | |

| Lower application temperature | °F | -40 | |

| Thermal conductivity | [W/m x K] | 0.24 | ASTM C 177 |

| Coefficient of thermal expansion (at 73°F) | [K-1 x 10-5] | 8 | DIN 53752 |

| Electrical properties | |||

| Specific volume resistance | Ωcm | > 1013 | DIN IEC 93 |

| Surface resistance | Ω | > 1011 | DIN 53482 |

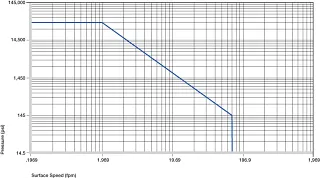

Permissible p x v values for iglide® Q2 plastic bushings running dry against a steel shaft, at 68°F

Permitted p x v values

For iglide® Q2 plastic bushings with 0.03 inches (1 mm) wall thickness under dry running conditions against a steel shaft, at 68°F, installed into a steel housing.

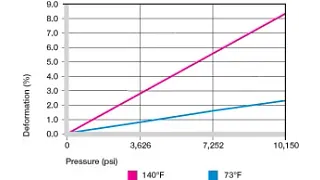

Deformation under load and temperatures

Compressive Strength

iglide® Q2 plastic bushings stand for high load capacities and good abrasion resistance at high loads. Solid lubricants reduce the coefficient of friction and improve the resistance to wear, which was markedly improved as compared to other iglide® plastic bushings for high load pivoting applications. iglide® Q2 plastic bushings are self lubricating and suitable for any motion.

The graph shows the elasticity deformation of iglide® Q2 plastic bushings during radial loading. Plastic deformation can occur, this depends on the applied pressure.

Permitted surdace speeds

The typical applications for iglide® Q2 plastic bushings are high load pivoting motions at comparatively low speeds. Independently of that, relatively high speeds are still attainable. The speeds shown in the table are threshold values for minimal bushing loads. As loads increase, the admissible speed is reduced with higher loads due to the limitations of the pv value.

| fpm | Rotary | Oscillating | Linear |

|---|---|---|---|

| Constant | 197 | 137 | 787 |

| Short-term | 393 | 275 | 984 |

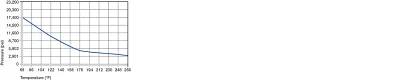

Temperatures

iglide® Q2 is a very temperature resistant material. The short-term temperature exposure limit is at +428 °F. The long-term upper temperature limit of +266 °F permits the broad use in applications typical for the agricultural, utility vehicle or construction equipment fields. However, the pressure resistance of iglide® Q2 plastic bushings declines as temperatures increase. When considering temperatures, the additional frictional heat in the bushing system must be taken into account.

| iglide® Q2 | Application temperature |

|---|---|

| Lower | -40°C |

| Upper, long-term | +266°F |

| Upper, short-term | +392°F |

| Additional axial securing | +176°F |

| Temperature limits for iglide® Q2 |

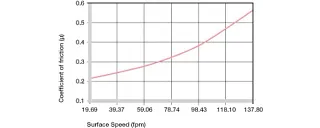

Coefficients of friction as a function of the running speed; p = 108 psi

Friction and wear

iglide® Q2 has a low coefficient of friction. Please note that a gliding partner with a rough surface finish will increase the friction. The highest coefficients of friction occur at 40 rms. For iglide® Q2 a ground surface with an average roughness range of 4 - 16 rms is recommended. Furthermore, the coefficient of friction of iglide® Q2 plastic bushings largely depends on the speed and load. As the speed increases, the coefficient of friction will quickly increase as well. However, as the load is reduced, the coefficient of friction initially drops significantly, then moderately.

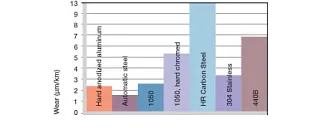

Wear, rotating application with different shaft materials, p = 108 psi, v = 98 fpm

Shaft materials

Generally, we recommend the use of hardened shafts for use in high load applications. Furthermore, even at low to medium loads, iglide® Q2 will attain increased service life with "hard" shafts as compared to "soft" shafts.

But for low load applications, the results are outstanding with free cutting steel as well. For high loads, the wear in pivoting applications is much lower than for rotations.

Chemical resistance

iglide® Q2 plastic bushings have good resistance to chemicals. They are resistant to most lubricants. The resistance is only limited for acids

| Medium | Resistance |

|---|---|

| Alcohols | + |

| Hydrocarbons, chlorinated | + |

| Greases, oils, without additives | + |

| Fuels | + |

| Weak acids | 0 to - |

| Strong acids | - |

| Weak alkaline | + |

| Strong alkaline | 0 |

| + resistant | 0 conditionally resistant | - non-resistant | |

| glide® Q2 chemical resistance | |

| All specifications at room temperature [+68 °F] iglide® Q2 chemical resistance |

Radioactive rays

iglide® Q2 plastic bushings are radiation resistant up to a radioactive intensity of 3 x 102 Gy.

UV-resistant

iglide® Q2 are permanently resistant to UV radiation.

Vacuum

The low water elements degas in the vacuum. Applications under vacuum conditions are possible with restrictions.

Electrical properties

iglide® Q2 plastic bushings are electrically insulating

| Specific volume resistance | Surface resistance |

|---|---|

| > 1013 Ωcm | > 1013 Ω |

Installation tolerances

iglide® Q2 plastic bushings are standard bushings for shafts with tolerance h (minimum recommendation is h9).

The bushings are designed for press-fit in a housing with h7 tolerance. After the installation in a housing with nominal diameter, the inner diameter of the bushing automatically adjusts to the E10 tolerance.

| Diameter d1 [mm] | Shaft h9 [mm] | iglide® Q2 E10 [mm] | Housing H7 [mm] |

|---|---|---|---|

| Up to 3 | 0 - 0,025 | +0,014 +0,054 | 0 +0,010 |

| > 3 bis 6 | 0 - 0,030 | +0,020 +0,068 | 0 +0,012 |

| > 6 bis 10 | 0 - 0,036 | +0,025 +0,083 | 0 +0,015 |

| > 10 bis 18 | 0 - 0,043 | +0,032 +0,102 | 0 +0,018 |

| > 18 bis 30 | 0 - 0,052 | +0,040 +0,124 | 0 +0,021 |

| > 30 bis 50 | 0 - 0,062 | +0,050 +0,150 | 0 +0,025 |

| > 50 bis 80 | 0 - 0,074 | +0,060 +0,180 | 0 +0,030 |

| > 80 bis 120 | 0 - 0,087 | +0,072 +0,212 | 0 +0,035 |

| > 120 bis 180 | 0 - 0,100 | +0,085 +0,245 | 0 +0,040 |

| Table 07: Important tolerances for iglide® Q2 plastic bushings according to ISO 3547-1 after the press-in |

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert