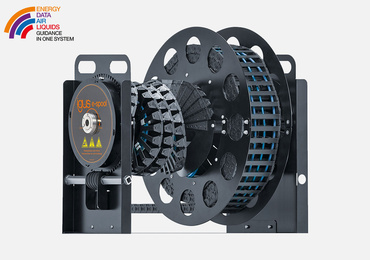

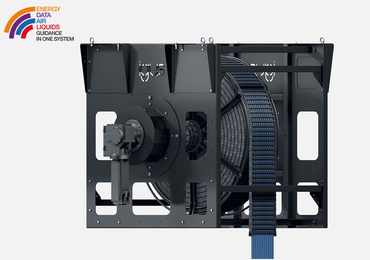

Guide many different cables within confined spaces. e-spool® uniquely combines two different energy supply systems: A standard e-chain® is guided by one roller and provides anytime the exactly correct length and tension of the energy supply system by the use of an integrated retaining spring. In the start position, the e-chain® is completely rolled up to save space. The twisterband connects the roll to the shaft block, which acts as the interface to the permanently installed cables.

Please contact us if you have one of the following application parameters:

We can assist you with a turnkey, fully assembled solutions or answer any questions you may have with a custom project.

Dan Thompson

Product Manager - North America

(800) 521-2747

A: The igus® e-spool® is an alternative to traditional cable reels, which are used to guide cables and hoses in confined spaces. The e-spool® system can guide several cables or media lines, including power, control or pneumatics, in one reel. In most cases, the e-spool® runs without electrical power, making it very easy to use, but for some unique applications it can also be developed with a motorized drive solution. It is easy to install, flexible, space-saving and extremely reliable. The system is designed with two different igus® energy supply systems in an innovative way. First, a standard igus® E2/000 e-chain® is guided on a steel spool. An integrated retraction spring within the spool provides retraction force and manages any slack. Additionally, an igus® twisterband connects the rotating spool to the base structure, where the fixed cables enter the system. The twisterband is what makes the e-spool® truly unique, as it eliminates an array of complications that typically come with other cable reels.

A: In traditional cable reels, a cable is run from the source (panel box, PLC, etc) to the fixed point of a slip ring. A second cable is then run from the rotational point of a slip ring to the end effector (lighting truss, assembly tool, etc.). This requires two lengths of cable, with four ends to be terminated. More terminations mean more installation labor and more points of potential failure. In an e-spool®, a single continuous cable is run from the source to the end effector without any intermediate terminations, improving the quality of the electrical signal and minimizing the risk of failure. The e-spool® is also designed to be much more versatile in what types of energy it can carry. In traditional cable reels, only one cable can be used per reel. Traditional solutions also require different types of reels for different energy sources, which have different form factors and must be purchased from multiple different suppliers.

A: The e-spool® design is also optimized for extended service life. It is expected to achieve between 70,000 and 200,000 strokes, depending on the application, while traditional cable reels often require service at a lesser number of cycles. In the igus® test lab, the e-spool®’s spring was tested in respect to its service life expectancy and the results were superior. In all tests, the e-spool® achieved a minimum service life of at least 70,000 strokes. Once maximum service life is reached, only the spring pack must be exchanged, which is a short 15 minute service effort. Once the spring is replaced, the e-spool® is ready to deliver another full service period, with all other components lasting for an extended period of time.

A: Along with the technical benefits of e-spool®, the cost can also be lower than traditional solutions. Light-duty industrial cable reels can be offered at a very low cost, but they are not rated for automated operation. Medium-duty industrial cable reels rated for automated operation are only slightly less expensive than e-spool®s. However, since traditional industrial reels can only guide one cable per reel, the costs become much greater when multiple cables are involved. Since the e-spool® can handle multiple cables in one reel, overall costs are likely to be lower in these scenarios.

A: The e-spool®’s quiet operation is another reason that it is well-suited for noise sensitive applications such as stage installations. In the igus® test laboratory, which is the largest in the industry, the e-spool® was intensely tested for its noise emissions during operation. The e-spool® was able to reach noise levels below 46dB (A) in the test—incredibly quiet results.

A: Aside from the standard offerings, igus® develops customized solutions as well. There are standard systems available with special additions, including systems with tubes, RBR chains, and stainless or colored systems. There are also more custom-built options, including e-spool®s designed for longer travels, systems with a different chain or custom changes to the steel parts to better integrate to a customer’s machine.

A: The unique structure of the e-spool® can put some mechanical stress on cables, so in order to help relieve these strains, there are a few guidelines that should be followed when filling an e-spool® with cables. Shielded cables designed for continuous torsional flexing such as chainflex® CFROBOT cables should be used when the maximum possible service life is desired. Cables should be placed side by side in the linear chain and never stacked on top of each other. Wherever possible, separators should be used to protect cables from becoming crossed or tangled. Cables should also be inserted according to diameter and/or bend radius, with the smallest cables towards the inside of the carrier and the increasingly larger cables towards the outside. Strain relief should be installed at both ends of the cable.

A: The twisterband is the brainchild of igus® engineers; it is the component in the e-spool® that allows the system to function without any slip rings. It is a plastic energy chain that allows rotary movement in a compact space. It provides maintenance-free guidance in confined spaces, and fully secures the media it guides. Rotary motion up to 7,000 degrees horizontally and 3,000 degrees vertically is possible, as well as speeds up to 360 degrees per second. This particularly novel component eliminates an array of possible complications when the e-spool® is applied in any given application. Since energy or media can be guided together with continuous end-to-end connection, and the rotary motion required to roll and unroll the e-chain® is done via a twisterband solution, there is no need for slip rings.

A: Though slip rings provide a functional solution to transfer current through a rotational junction, they are sensitive to external and environmental factors such as dust, dirt, moisture or other forms of contamination, and require regular maintenance to remain operational. There are various problems that can lead to maintenance or complete replacement of slip rings, with the most common issue being wear or threading of brushes. As the brush wears down, it wears fine grooves into the contact ring, while also covering the inside of the slip ring in fine dust from the brush wear. The brushes themselves and their retaining springs must then be replaced, which can be a messy and tedious process that also requires powering down the electrical system to safely work on the internal components. Loss of contact between the brush and the ring is another cause of failure, which can cause unexpected faults in production machinery or interruption of electrical current in the case of a lighting truss or similar application. Copper or steel slip rings are also inclined to corrode in wet or outdoor environments, especially if they aren’t properly sealed, further increasing the risk of failure. In short, slip rings are simply prone to overall wear, therefore increasing the likelihood of ongoing problems and the need for regular maintenance

A: When to use the e-loop® system:

When to use another system:

Monday to Friday from 8 am - 8 pm

24h