Change Language :

iglide® J350 - Material data

Materials table

| General features | Unit | iglide® J350 | test method |

|---|---|---|---|

| Density | g/cm³ | 1,44 | |

| Color | yellow | ||

| Max. moisture absorption at 73°F/50% R. H. | Wt.-% | 0.3 | DIN 53495 |

| Max. moisture absorption | Wt.-% | 1.6 | |

| Coefficient of surface friction, dynamic, against steel | µ | 0.10 - 0.20 | |

| P x v value, max. (dry) | psi x fpm | 13,000 |

Mechanical properties

| General features | Unit | iglide® J350 | test method |

|---|---|---|---|

| Modulus of elasticity | psi | 290,100 | DIN 53457 |

| tensile strength at 68° F | psi | 7,977 | DIN 53452 |

| Compressive strength | psi | 8,702 | |

| Maximum recommended surface pressure (68° F) | psi | 8,702 | |

| Shore D hardness | 80 | DIN 53505 |

Physical and thermal properties

| General features | Unit | iglide® J350 | test method |

|---|---|---|---|

| Upper long-term application temperature | °F | 356 | |

| Upper short-term application temperature | °F | 428 | |

| Lower application temperature | °F | -148 | |

| Thermal conductivity | W/m x K | 0.24 | ASTM C 177 |

| Coefficient of thermal expansion (at 73° F) | K^-1 x 10^-5 | 7 | DIN 53752 |

Electrical properties

| General features | Unit | iglide® J350 | test method |

|---|---|---|---|

| Specific volume resistance | Ωcm | > 10^13 | DIN IEC 93 |

| Surface resistance | Ω | > 10^10 | DIN 53482 |

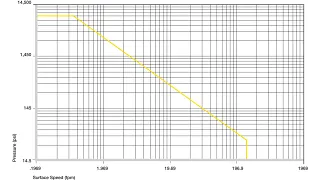

Permitted p x v values

An outstanding bushing for rotating applications and for a wide range of different shaft materials. With iglide® J350 plastic bushings, the lifetime can often be increased for applications between 145 psi and 7,252 psi. In addition, the high temperature resistance makes it a very versatile material.

Permitted p x v values for iglide® J350 plastic bushings running dry against a steel shaft, at 68°F.

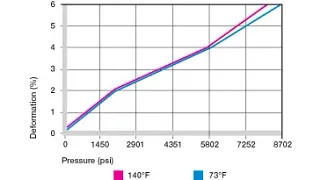

Deformation under load and temperatures

Surface pressure

iglide® J350 plastic bushings are adequate for medium and high loads. The graph shows the elastic deformation under different temperatures. At the recommended maximum surface pressure of 8702 psi the deformation is less than 6%.

Permissible surface speed

Permitted surface speeds

iglide® J350 plastic bushings are well suited for low and medium speeds, both in rotating and oscillating applications. The wear rates are much better in rotating applications. And linear motions can be well mounted with iglide® J350.

| fpm | Rotary | Oscillating | Linear |

|---|---|---|---|

| Constant | 256 | 197 | 787 |

| Short-term | 591 | 453 | 1575 |

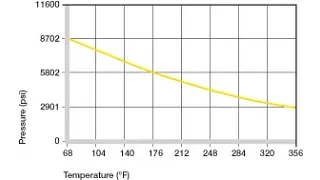

Recommended maximum permissible static surface pressure of iglide® J350 plastic bushing as a result of the temperature

Temperatures

The temperature resistance makes iglide® J350 the very universal material for plastic bushings in different industries. Application temperatures up to +428°F are permitted on the short term. At the temperatures above +302°F the bushing should be mechanically fixed in the bore. Higher temperatures may result in a loss of the pressfit of the plastic bushings, potentially allowing the bushing to drift within the housing bore.

The wear rate of the iglide® J350 plastic bushings changes very little at higher temperatures. Sometimes the wear decreases even at +212°F. Generally, the wear rates in the tests are very similar in temperatures between +68°F and +302°F.

The iglide® J350 is a highly wear-resistant plastic bushing, which can also be used at higher temperatures. The combination of excellent tribological and thermal properties fills a gap in the group of long life materials.

| iglide® J350 | Application temperature |

|---|---|

| Lower | -148°F |

| Upper, long-term | +356 °F |

| Upper, short-term | +428 °F |

| Additional axial securing | +302°F |

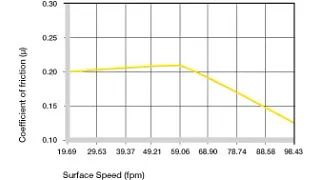

Coefficients of friction as a function of the running speed, p = 108 psi

Friction and wear

The coefficients of friction of iglide® J350 in dry operation on a steel shaft is very good. It is even lower at high speed, which makes the material very suitable for permanently dry-running application at high rotation speed. iglide® J350 plastic bushings are clearly superior to other bushing materials in rotating applications over 290 psi. A lifetime of iglide® J350 can be several times higher.

| iglide® J350 | Dry | Grease | Oil | Water |

|---|---|---|---|---|

| Coefficients of friction μ | 0.10–0.20 | 0.09 | 0.04 | 0.04 |

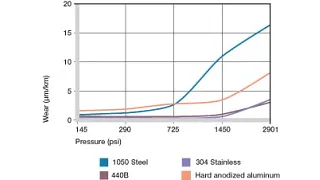

Wear of iglide® J350 with different shaft materials in rotational applications as a function of the pressure

Shaft Materials

The graphs show results of testing different shaft materials with bushings made of iglide® J350. iglide® J350 plastic bushings can be combined with various shaft materials.

One shaft - bushing combination stands out when looking at the wear results of the test: iglide® J350 with 304 stainless steel. There are not many bushing materials that are suitable for the otherwise rather difficult shaft partner stainless steel and achieve best wear rates. Excellent wear results can also be observed with hard-anodized aluminum shafts. Please contact us in case the shaft material scheduled by you is not included here.

Chemical Resistance

+ resistant 0 partially resistant - non-resistant

Chemical resistance of iglide® J350

All data given concerns the chemical resistance at room temperature (68° F)

| Medium | Resistance |

|---|---|

| Alcohol | + |

| Hydrocarbons, chlorinated | + to 0 |

| Greases, oils, without additives | + |

| Fuels | + |

| Weakacids | + |

| Strong acids | + to 0 |

| Weak alkaline | + |

| Strong alkaline | + |

Chemical Resistance

iglide® J350 plastic bushings are resistant to diluted acids and alkalis, alcohols, detergents and lubricants. iglide® J350 is affected by esters, ketones, chlorinated hydrocarbons, aromatics and highly polar solvents.

Radioactive rays

iglide® J350 plastic bushings are radiation resistant up to a radioactive intensity of 2 x 102 Gy.

UV-resistant

iglide® J350 plastic bushings are partially resistant against UV rays.

Vacuum

In a vacuum, iglide® J350 plastic bushings outgas only to a very small extent. The application in vacuum is possible only for dry bushings.

Electrical properties

iglide® J350 plastic bushings are electrically insulating.

| Specific volume resistance | > 10^13 Ωcm |

|---|---|

| Surface resistance | > 10^10 Ω |

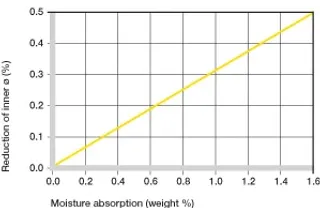

Influence of moisture absorption of iglide® J350 plastic bushings

Moisture Absorption

The moisture absorption of iglide® J350 is low and can be disregarded when using standard bushings. Even at full saturation the iglide® J350 does not absorb more than 1,6% of water.

| Diameter d1 [mm] | Shaft h9 [mm] | iglide® J3 E10 [mm] | Housing H7 [mm] |

|---|---|---|---|

| Up to 3 | 0 - 0,025 | +0,006 +0,046 | 0 +0,010 |

| > 3 to 6 | 0 - 0,030 | +0,010 +0,058 | 0 +0,012 |

| > 6 to 10 | 0 - 0,036 | +0,013 +0,071 | 0 +0,015 |

| > 10 to 18 | 0 - 0,043 | +0,016 +0,086 | 0 +0,018 |

| > 18 to 30 | 0 - 0,052 | +0,020 +0,104 | 0 +0,021 |

| > 30 to 50 | 0 - 0,062 | +0,025 +0,125 | 0 +0,025 |

| > 50 to 80 | 0 - 0,074 | +0,030 +0,150 | 0 +0,030 |

Installation tolerances

iglide® J350 plastic bushings are standard bushings for shafts with h-tolerance (recommended minimum h9). The bushings are designed for press-fit in a housing with h7 tolerance. After the installation in a housing with nominal diameter, the inner diameter of the bushings automatically adjusts to the F10 tolerance.

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert