Change Language :

iglide® A350 - Material data

General features of iglide® A350

Density

1.42 g/cm³

Colour

light blue

Max. moisture absorption at 73°F/50% R. H.

0.6 Wt.-% (DIN 53495)

Max. moisture absorption

1.9 Wt.-%

Coefficient of friction, dynamic, against steel

0.1 - 0.2 µ

P x v value, max. (dry)

11.500 psi x fpm

Mechanical features of iglide® A350

Modulus of elasticity (DIN 53457)

290.100 psi

Tensile strength at 68° F (DIN 53452)

15.950 psi

Compressive strength

11.310 psi

Permissible static surface pressure (68° F)

8.702 psi

Shore D hardness (DIN 53505)

76

Physical and thermal properties of iglide® A350

Upper long-term application temperature

+356 °F

Upper short-term application temperature

+410 °F

Lower application temperature

-148 °F

Thermal conductivity (ASTM C 177)

0.24 [W/m x K]

Coefficient of thermal expansion (at 73° F, DIN 53752)

8 [K-1 x 10-5]

Electrical properties of iglide® A350

Specific volume resistance (DIN IEC 93)

> 1011 Ωcm

Surface resistance (DIN 53482)

> 1011 Ω

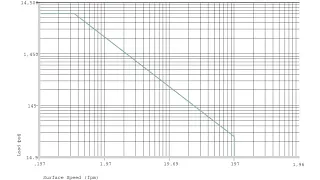

Permissible p x v values for iglide® A350 plastic bushings running dry against a steel shaft, at 68°F

Permitted p x v values

FDA compliant and wear-resistant at high temperatures.

A very universal bushing for applications in the food and pharmaceutical industries. Thanks to the FDA conformity, iglide® A350 plastic bushings can be used wherever unpackaged foodstuffs are processed. With their tribological and thermal properties they are genuine all-rounders in the food industry.

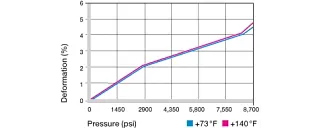

Deformation under load and temperatures

Surface Pressure

The graph shows the elastic deformation of iglide® A350 during radial loading. At the recommended maximum surface pressure of 2900 psi the deformation is less than 5%.

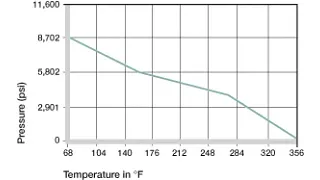

Recommended maximum permissible static surface pressure of iglide® A350 as a result of the temperature.

Temperatures

Its temperature resistance makes iglide® A350 an ideal material for a bushings in the food industry. The typical temperatures here reach up to +266°F, which is ideally covered by iglide® A350. Application temperatures up to +410°F are permitted on the short term. Please note that at temperatures over +284°F, the pressfit forces of the bushings may decrease and an additional axial securing device is recommended.

The wear rate of the iglide® A350 plastic bushings increases only minimally with higher temperatures. Tests have shown good wear results at +212°F on all tested shaft materials

iglide A350® temperature thresholds

Minimum: -148°F

Upper, long-term: +356°F

Upper, short-term: +410°F

Additional axial securing: +284°F

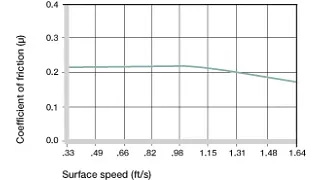

Coefficients of friction as a function of the running speed; p = 145 psi

Friction and wear

The coefficients of friction of iglide® A350 on a steel shaft is in the mid range. The friction decreases at temperatures, which is quite unusual in dry operation. The graph shows the connection. The wear rates of all tests with iglide® A350 show good results at a low level. The most wear resistant ones are often found among the iglide® plastic bushings for food contact.

Coefficients of friction

Dry: 0.1 - 0.2 µ

Grease: 0 09 µ

Oil: 0.04 µ

Water: 0.04 µ

Coefficients of friction for iglide® A350 against steel (Shaft finish = 40 rms, 50 HRC)

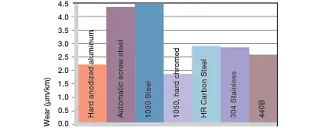

Wear, rotating application with different shaft materials, p = 145 psi, v = 59 fpm

Shaft Materials

The corrosion-resistant steels are rather considered natural for use in the food industry. The trials were therefore carried out especially on such materials. It has been shown that there is no clear favorite 440B and hard chrome-plated steel are both suitable. Hard anodized aluminum is also well suited for both linear and rotating movements.

Chemical Resistance

iglide® A350 plastic bushings are resistant to diluted acids and alkalis, alcohols and detergents. They are also resistant to most lubricants. The iglide® A350 plastic bushings are resistant to common cleaning agents used in the food industry. iglide® A350 is affected by esters, ketones, chlorinated hydrocarbons, aromatics and highly polar solvents.

+ resistant 0 partially resistant - non-resistant

All specifications at room temperature [+68°F]

Alcohols

+

Hydrocarbons, chlorinated

+ to 0

Greases, oils, without additives

+

Fuels

+

Weak acids

+

Strong acids

+

Weak alkaline

+

Strong alkaline

+

Radioactive rays

iglide® A350 plastic bushings are radiation resistant up to a radiation intensity of 2 x 102 Gy.

UV-resistant

iglide A350® plastic bushings are well resistant against UV rays.

Vacuum

In vacuum, iglide® A350 degases. The application in vacuum is possible only for dry bushings.

Electrical properties

iglide® A350 plastic bushings are electrically insulating.

Specific volume resistance

> 1011 Ωcm

Surface resitance

> 1011 Ω

Influence of moisture absorption of iglide® A350 plastic bushings

Moisture Absorption

The moisture absorption of iglide® A350 is low and can be disregarded when using standard bushings. Even at full saturation the iglide® A350 does not absorb more than 1.9% of water.

Maximum moisture absorption

by +23 °C/50 % r. F.: 0.6 weight-%

Max. water absorption: 1.9 weight-%

Installation tolerances

iglide® A350 plastic bushings are standard bushings for shafts with h-tolerance (recommended minimum h9). The bushings are designed for press-fit in a housing with h7 tolerance. After the installation in a housing with nominal diameter, the inner diameter of the bushing automatically adjusts to the F10 tolerance.

| Diameter d1 [mm] | Shaft h9 [mm] | iglide® A350 F10 [mm] | Housing H7 [mm] |

|---|---|---|---|

| Up to 3 | 0 - 0,025 | +0,006 +0,046 | 0 +0,010 |

| > 3 bis 6 | 0 - 0,030 | +0,010 +0,058 | 0 +0,012 |

| > 6 bis 10 | 0 - 0,036 | +0,013 +0,071 | 0 +0,015 |

| > 10 bis 18 | 0 - 0,043 | +0,016 +0,086 | 0 +0,018 |

| > 18 bis 30 | 0 - 0,052 | +0,020 +0,104 | 0 +0,021 |

| > 30 to 50 | 0 - 0,062 | +0,025 +0,125 | 0 +0,025 |

| > 50 to 80 | 0 - 0,074 | +0,030 +0,150 | 0 +0,030 |

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert