Change Language :

iglide® P - Material data

Materials table

| General features | Unit | iglide® P | Test method |

|---|---|---|---|

| Density | g/cm3 | 1.58 | |

| Color | Black | ||

| Max. humidity absorption at 73° F/50% R. H. | Wz.-% | 0.2 | DIN 53495 |

| Max. water absorption | Wt.-% | 0.4 | |

| Coefficient of surface friction, dynamic, against steel | µ | 0.06-0.21 | |

| p x v value, max. (dry) | psi x fpm | 11,000 | |

| Mechanical properties | |||

| Modulus of elasticity | psi | 768,700 | DIN53457 |

| Tensile strength 68 °F | psi | 17,400 | DIN53452 |

| Compressive strength | psi | 9,572 | |

| Permissible static surface pressure (68 °F) | psi | 7,252 | |

| Shore D hardness | 75 | DIN53505 | |

| Physical and thermal properties | |||

| Max. long-term application temperature | °F | 266 | |

| Max. short-term application temperature | °F | 392 | |

| Min. application temperature | °F | -40 | |

| Thermal conductivity | [W/mxK] | 0.25 | ASTM C 177 |

| Coefficient of thermal expansion | [K-1x10-5] | 4 | DIN 53752 |

| Electrical properties | |||

| Specific volume resistance | Ωcm | >1013 | DIN IEC 93 |

| Surface resistance | Ω | >1012 | DIN 53482 |

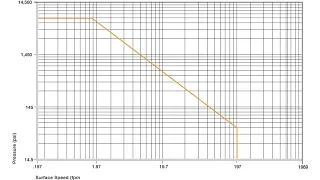

Permitted p x v values

For iglide® P plastic bushings with 0.039 inches wall thickness in dry operation against a steel shaft, at 68° F, installed in a steel housing.

The iglide® P plastic bushings are a cost-effective, maintenance-free bushing solution for the user. Compared to iglide® G300, bushing made of iglide® P are better suited for rotating motions and high loads.

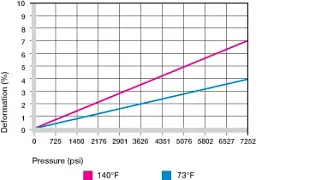

Deformation under load and temperatures

Compressive Strength

The graph shows the elastic deformation of iglide® P with radial loads. At the maximum permissible load of 5075 psi, the deformation is less than 3% at room temperature.

Permitted surface speeds

The iglide® P plastic bushings are maintenance-free bushings developed for low to medium surface speeds. The maximum values stated in the table can be attained only with very low surface pressure. The specified maximum speed is the speed at which the long-term permitted temperature is reached by an increase in heat through friction.

| fpm | Rotating | Oscillating | Linear |

|---|---|---|---|

| Constant | 196 | 137 | 590 |

| Short-term | 393 | 275 | 787 |

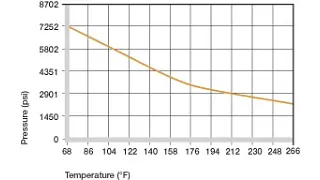

Maximum recommended surface pressure dependent on the temperature

Temperatures

Even with its maximum long-term application temperature of 266° F, iglide® P does not approach the values of iglide® G300. With a short-term permitted maximum temperature of 392° F, a paint drying process is still possible without further load.

With increasing temperatures, the compressive strength of iglide® P plastic bushings decreases. The graph clarifies this connection.

The temperatures prevailing in the bushing system also have an influence on the bushing wear. Rising temperatures mean higher wear.

| iglide® P | Application temperature |

|---|---|

| Lower | - 40 °F |

| Upper, long-term | + 266 °F |

| Upper, short-term | + 392 °F |

| Additional axial securing | + 194 °F |

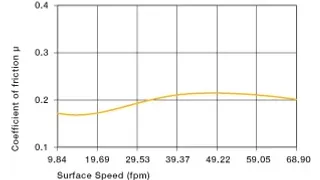

Coefficients of friction dependent on the surface speed, p = 108 psi

Friction and wear

The coefficient of friction alters like the wear resistance with increasing load. For iglide® P the coefficient of friction slightly increases with increasing speed. The graph shows how strongly the coefficient of friction drops with increasing load. From about 870 psi, the coefficient of friction is already below 0.1.

For iglide® P plastic bushing a ground surface with an averageroughness range of 4 - 8 rms is recommended for the shaft. Both smoother and rougher shafts finishes clearly increase the friction.

Coefficients of friction for iglide® P against steel (Shaft finish = 40 rms, 50 HRC)

| iglide® P | Dry | Grease | Oil | Water |

|---|---|---|---|---|

| Coefficients of friction µ | 0.06 - 0.21 | 0.09 | 0.04 | 0.04 |

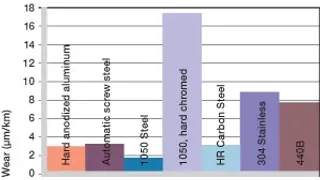

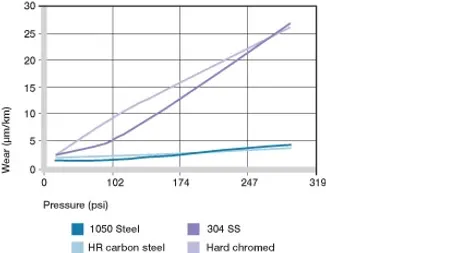

Wear, rotating application with different shaft materials, load p = 108 psi, v = 98 fpm

Shaft materials

The graphs show a summary of the results of tests with different shaft materials conducted with plastic bushings made of iglide® P.

In rotating applications, the wear of iglide® P is very low with Cold Rolled Steel and HR Carbon Steel shafts. On the other hand, the bushings on 303 Stainless Steel shafts as well as hard-chromed shafts result in higher wear than other shaft materials even in the lowload range. For example, at a load of 290 psi Cold Rolled Steel is six times better than 303 Stainless Steel.

The wear rates of low-stressed bushings in pivoting motions with most shaft materials are lower than in rotating applications. For this purpose, the Cold Rolled Steel and hard-chromed shafts prove to be the best sliding partners. Also, the 303 Stainless Steel shafts that have poor results for rotation, are excellent for the oscillating application.

Please contact us in case the shaft material scheduled by you is not included in this diagram.

Important tolerances for iglide® P plastic bushings according to ISO 3547-1 after the press-fit.

iglide® P plastic bushings are standard bushings for shafts with h-tolerance (recommended minimum h9).

After the installation in a housing bore with H7 tolerance, the inner diameter of the bushing automatically adjusts to the E10 tolerance.

| Diameter d1 [inch] | Shaft h9 [inch] | iglide® P E10 [inch] |

|---|---|---|

| Up to 0.019685 | 0 - 0.0009846 | +0.000551 + 0.0021260 |

| > 0.1181 to 0.2362 | 0 - 0.0011811 | +0.000787 + 0.0026772 |

| > 0.2362 to 0.3937 | 0 - 0.0014173 | +0.000984 + 0.0032677 |

| > 0.3937 to 0.7087 | 0 - 0.0016929 | +0.001260 + 0.0040157 |

| > 0.7087 to 1.1811 | 0 - 0.0020472 | +0.001574 + 0.0048819 |

| > 1.1811 to 1.9685 | 0 - 0.0024409 | +0.001969 + 0.0059055 |

Chemical resistance

iglide® P plastic bushings have a good resistance against chemicals. They are resistant to most lubricants. The iglide® P is not affected by most weak organic and inorganic acids.

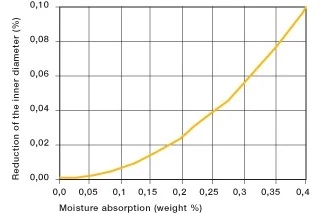

The humidity absorption of iglide® P plastic bushings amounts to about 0.2% in standard climatic conditions. The saturation limit in water is 0.4%. This minor moisture absorption is clearly below the values of iglide® G300.

Radioactive rays

Plastic bushings made of iglide® P are conditionally usable under radioactive radiation. They are resistant up to a radiation intensity of 5 x 10² Gy.

UV-resistant

iglide® P plastic bushings provide a comparably good UV resistance.

Vacuum

The existent humidity of iglide® P plastic bushings degasses in the vacuum. The use in vacuum is possible only limitedly.

| Medium | Resistance |

|---|---|

| Alcohol | + |

| Hydrocarbonschlorinated | - |

| Greases, oils, without additives | + |

| Fuels | + |

| Weak acids | o |

| Strong acids | - |

| Weak alkaline | - |

| Strong alkaline | - |

| + resistant 0 conditionally resistant - non-resistant |

Electrical properties

iglide® P plastic bushings are electrically insulating.

| Specific volume resistance | Surface resistance |

|---|---|

| > 1013 Ωcm | > 1012 Ω |

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert