Change Language :

iglide® TX1 - Material data

Material table

| General features | Unit | iglide® TX1 | Test method |

|---|---|---|---|

| Density | g/cm³ | 2,1 | |

| Color | grey-green | ||

| Max. humidity absorption at 73°F/50% R. H. | %weight | 0,2 | DIN 53495 |

| Max. water absorption | %weight | 0,5 | |

| Coefficient of surface friction, dynamic, against steel | µ | 0,09 - 0,37 | |

| pv value, max. (dry) | psi x fpm | 26,000 | |

| Mechanical properties [bold text] | |||

| Bending E-module | psi | 1,740,000 | DIN 53457 |

| Tensile strength at +68 °F | psi | 7,977 | DIN 53452 |

| Compressive strength | psi | 31,910 | |

| Maximum recommended surface pressure (68 °F) | psi | 29,000 | |

| Store D-hardness | 94 | DIN 53505 | |

| Physical and thermal properties [bold text] | |||

| Max. long term application temperature | °F | +248 | |

| Max. short term application temperature | °F | +338 | |

| Minimum application temperature | °F | -76 | |

| Thermal / heat conductivity | [W/m x K] | 0,24 | ASTM C 177 |

| Coefficient of thermal expansion (at 73 °F) | [K^-1 x 10^-5] | 3 | DIN 53752 |

| Electrical properties [bold text] | |||

| Specific forward resistance | Ωcm | >10^11 | DIN IEC 93 |

| surface resistance | Ω | >10^13 | DIN 53482 |

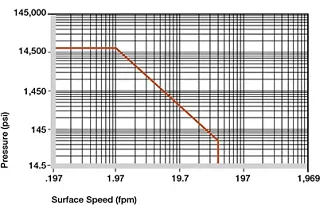

Fig. 01: Permissible pv values for iglide® TX1 plain bearings in dry operation against a steel shaft at +68°F.

X = Sliding speed [fpm]

Y = Load [psi]

iglide® TX1 plain bearings stand for very high load capacity with high radial loads combined with good abrasion resistance. The special design on the one hand ensures high dimensional stability through the long fiber winding, and on the other hand a lubrication- and maintenance-free operation is possible thanks to solid lubricants. High resistance to dirt and media round off the property profile.

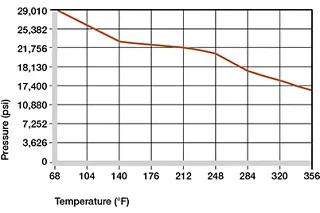

Figure 02: Maximum recommended surface pressure dependent on the temperature (29,000 psi to +68 °F)

X = Temperature [°F]

Y = Load [psi]

Mechanical properties

With increasing temperatures, the compressive strength of iglide® TX1 plain bearings decreases. Fig. 02 clarifies this connection. With the short-term permitted application temperature of +338 °F, the permitted surface pressure still amounts to 14,500 psi. Maximum recommended surface pressure represents a mechanical material parameter. Tribological conclusions cannot be drawn from it.

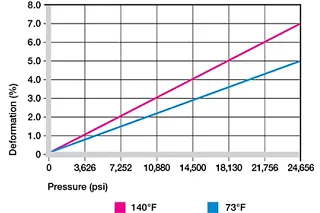

Figure 03: Deformation under load and temperatures

X = Load [MPa]

Y = Deformation [%]

Figure 03 shows the elastic deformation of iglide® TX1 with radial loads.

Permitted surface speeds

Typical applications for iglide® TX1 plain bearings are highly loaded swiveling motion with rather low speeds. Independently of that, relatively high speeds are still attainable. The speeds stated in Table 03 are limit values for the low bearing loads. They say nothing about the wear resistance in these parameters.

| fpm | Rotary | Oscillating | Linear |

|---|---|---|---|

| Constant | 78 | 39 | 197 |

| Short-term | 177 | 98 | 393 |

| Table 03: Maximum surface speeds |

Temperatures

iglide® TX1 is a very temperature-resistant material. The upper long-term application temperature of 248°F allows extensive use, e.g. in typical applications in the agricultural, commercial vehicle or construction vehicle sector. The press-in and push-out forces of iglide® TX1 plain bearings are at a very high level over the entire temperature range, which makes an additional axial securing usually unnecessary. Some decrease to a still very high level can be observed from +212°F, which is why an axial locking can be recommended in the individual case from this temperature level on. The additional friction heat in the bearing system should be considered in the temperature observations.

Friction and wear

Please note that a gliding partner with a rough surface finish will increase the friction. Extremely smooth shafts can likewise increase the coefficient of friction. We recommend shaft surface finishes (Ra) of 0.4 to a maximum of 0.7 µm. The coefficient of friction of iglide® TX1 plain bearings also depends to a large extent on the speed and load. With increasing surface speed, the friction coefficient increases rapidly. However, with load the coefficient of friction decreases continuously.

| iglide® TX1 | Dry | Grease | Oil | Water |

|---|---|---|---|---|

| Coefficients of friction µ | 0,09-0,37 | 0,09 | 0,04 | 0,04 |

| Table 04: Coefficients of friction against steel (Ra = 1 µm, 50 HRC) |

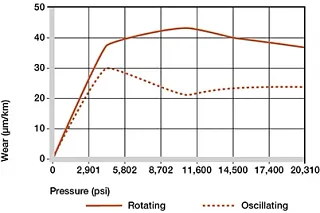

Fig. 07: Wear with oscillating and rotating applications with Cf53 as a function of the load

X = Load [psi]

Y = Wear [μm/km]

A = Rotating | B = Oscillating

Shaft materials

Generally, we recommend the use of hardened shafts for use in high load applications. This is especially true when using iglide® TX1. But still acceptable wear rates are also achieved on soft shafts in the high load swivel below 14,500 psi. Comparison of the wear rate in rotation and swiveling in Fig. 07 shows that the strength of iglide® TX1 lies in the highly loaded swivel.

Further properties

Chemical resistance

Radioactive rays The iglide® TX1 bearings are radiation resistant up to a radiation intensity of 2 • 102 Gy.

UV-resistant igubal® TX1 plain bearings are permanently resistant against UV rays.

VacuumThe low water elements degas in the vacuum. Applications under vacuum conditions are possible with restrictions.

| Medium | Resistance |

|---|---|

| Alcohols | 0 |

| Hydrocarbons | + |

| Greases, oils without additives | + |

| Fuels | + |

| Diluted acids | + |

| Strong acids | - |

| Diluted bases | + |

| Strong bases | - |

| + Resistant 0 Conditionally resistant - Not resistant | |

| All specifications at room temperature [68 °F] | |

| Table 02: Chemical resistance of iglide® TX1 |

Electrical properties iglide® TX1 bearings are electrically insulating.

| Specific forward resistance | > 10^11 Ωcm (not bold) | DIN IEC 93 (not bold) |

|---|---|---|

| Surface resistance [bold text] | >10^13Ω | DIN 53482 |

Humidity absorption / moisture absorption

The moisture absorption of iglidur® TX1 plain bearings amounts to about 0.2% in standard climatic conditions. The saturation limit in water is 0,5%.

Installation tolerances

iglide® TX1 plain bearings are standard bearings for shafts with h-tolerance (recommended minimum h9). The bearings are designed for press-fit in a housing with h7 tolerance. After the installation in a housing with nominal diameter, the inner diameter of the bearing automatically adjusts as stated in the standard case.

| Diameter d1 [mm] | Shaft h9 [mm] | iglide® TX1 [mm] | Housing H7 [mm] |

|---|---|---|---|

| > 20 bis 40 | 0 - 0,052 | +0,020 +0,154 | 0 +0,021 |

| > 40 bis 70 | 0 - 0,062 | +0,025 +0,175 | 0 +0,025 |

| > 70 bis 80 | 0 - 0,074 | +0,050 +0,200 | 0 +0,030 |

| Table 05: Important tolerances for iglide® TX1 plain bearings according to ISO 3547-1 after being pressed in, without possible expansion of the housing bore |