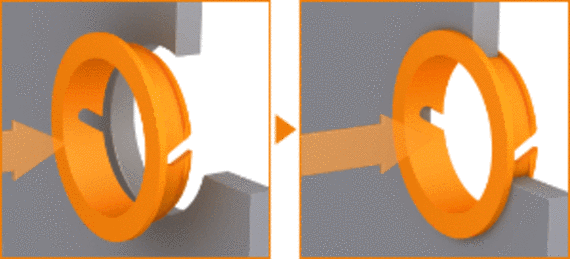

Due to their shape, the new iglide® K250 clip bearings can be easily clipped into sheet metals without getting lost. Thanks to its temperature resistance, the new material recipe also allows for absolute dimensional stability beyond the e-coating process.

A challenge that automotive manufacturers face: cost pressure, mass production and increasing demands regarding quality and feel have to be brought in line. They have to produce elegant surfaces as cost-effectively as possible and realize clear lines and shapes. At the same time, moving parts should work without any sort of rattling (i.e. bearing clearance) and squeaking. In other words: the perfect user experience. This applies not only to vehicles, but also to kitchen devices or furniture.

One problem: the manufacturing processes often set additional requirements for the plain bearings. A mixture of bad installation tolerances in stamped sheet metals, high assembly forces as well as hot temperatures and aggressive chemicals during painting in immersion baths will break any metal plain bearing. Either the outer steel base layer rusts or the sensitive PTFE sliding film is damaged. The result: rattling and squeaking.

The iglide® K250 clip bearings are not only suitable for seat adjustments in the automotive industry. The flexible and temperature-resistant material can also be used in this form for sheet metal feedthrough in surroundings with high temperatures or generally changing temperature conditions. Due to their low moisture absorption, the mass of the plain bearings barely changes, even when in consistent contact with moisture. The clearance situation in the bearing mostly remains unchanged. Ideal application areas for iglide® K250 clip bearings are all sorts of sheet metal feedthrough in automotive, furniture and household technology or in mechanical engineering

Monday to Friday from 8 am - 8 pm

24h