Inquiry / Contact

igus® inc.

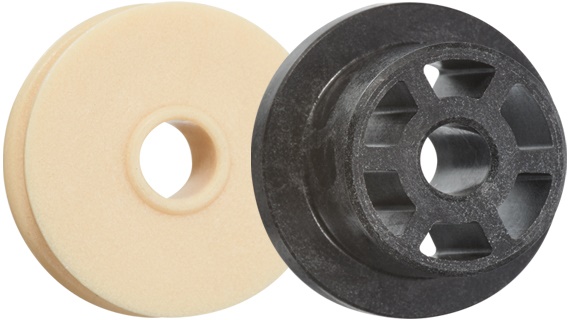

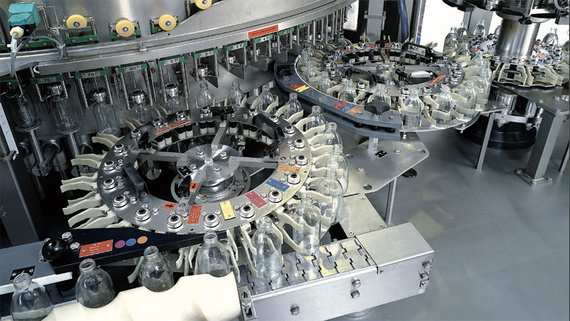

All iglide® materials consist of three components: base polymers, fibres and fillers, solid lubricants. As it is not possible for one universal material to fulfil all tasks equally well, there are different iglide® materials. Each has a different composition of the three components and a different application area.

Monday to Friday from 8 am - 8 pm

24h