Change Language :

Linear bearings, plain bearings, and e-chains for maintenance-free driver's cabs

The design of cabs in work machines such as cranes, agricultural machinery and construction machinery must meet high quality standards to ensure safety and productivity on the field, construction site or port. Wherever movement takes place - for example in the adjustment options of the seats, the control elements or when adjusting the displays - everything must run smoothly.

Thanks to dry operation, drylin linear bearings and iglidur plain bearings work maintenance-free and lubrication-free, permanently rattle-free and are insensitive to dirt, dust and corrosion. They are therefore suitable for use in the machine environment and can contribute to a long service life in the cabin. Here you can find out more about products, installation locations and advantages.

Prepared for the Onfield 4.0 driver's cab

The latest trend in cab design for agricultural machinery is the Onfield 4.0 cab. Tractors or harvesters such as combine harvesters are already often GPS-controlled and equipped with extensive sensors. So that the farmer can be productive even with a low workload, digital networking will continue to increase. Office tasks such as accounting should then be carried out from the agricultural machine. Displays with flexible adjustment options will thus shape the interior design even more. But the driver's seat must also be very flexible and must be able to be turned to face the side console, for example.

Installation Locations and Advantages of Motion Plastics in Agricultural Machinery

Linear adjustment displays & seat

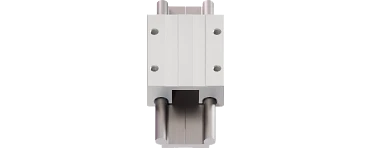

- Products: drylin W linear guides or drylin N miniature guides

- Advantages: dry-running, dirt-resistant and robust, durable, quiet operation

Cable guidance of driver's seat rotation

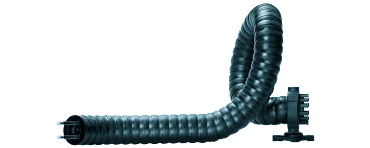

- Products: RBR rotary energy supply systems with a small internal E 2.1 e-chain

- Advantages: rotation angle up to 360°, light, compact, protected against corrosion

Cable guidance of driver's seat

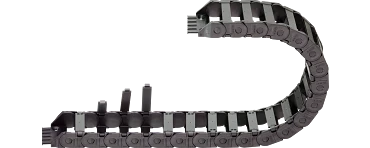

- Products: E 2.1 energy chains

- Advantages: long service life, very quiet operation, easy filling and assembly

Cable guidance of control elements

- Products: triflex 3D e-chain

- Advantages: for rotating and pivoting movements, cables safely guided

All products for the agricultural industry

Agriculture sample box

Motion plastics in driver's seats

Bearing products and e-chains for driver's cabs in cranes

Flexible seats for more safety with high productivity

Whether in a construction crane, port crane or intermodal crane, modern crane cabs are characterized above all by the driver's seats with a wide range of adjustment options. This not only applies to flexibly adjustable headrests and armrests. In order to always have an overview when lifting the load, the seats should be able to be moved linearly forwards and backwards and also be easy to tilt. This ensures high productivity with a high level of safety at the same time. Further adjustments in the crane cab are made with movable displays and control elements, and above all the master switch.

Installation Locations and Advantages of Motion Plastics in Cranes

Linear adjustment displays & seat

- Products: drylin W linear guides or drylin N miniature guides

- Advantages: dry-running, dirt-resistant and robust, durable, quiet operation

Bearing arrangement of master switch

- Products: igubal EGLM spherical bearings

- Advantages: corrosion-resistant, high dampening capacity, impact-resistant

Cable guidance of driver's seat

- Products: E 2.1 energy chains

- Advantages: long service life, very quiet operation, easy filling and assembly

Bearing arrangement of the doors

- Products: iglide G plain bearing

- Advantages: very good coefficients of friction, resistant to edge pressure, resistant to shocks and impacts, resistant to dirt and dust

Bearing arrangement of windshield wiper

- Products: iglide H2 plain bearing

- Advantages: low moisture absorption, corrosion-resistant, highly media-resistant, economical

Side console height adjustment

Products: linear axes and drylin E motors

Advantages: torsion-resistant double-shaft profile, powerful stepper motors with anti-rotation feature

Bearing products and e-chains for driver's cabs in construction machinery

Operate heavy machinery safely

Excavators, wheel loaders, tracked vehicles or transporters: the cab design also plays its part in the safe movement of heavy machinery. A high level of comfort, a good overview and a natural sitting position are required here. A wide range of seat adjustments, such as linear rails on the arm and headrests or plain bearings on the back adjustment, allow the correct seating position for every machine operator. They must also work maintenance-free when in contact with dirt and high humidity. In addition, the user must be able to rely on the flawless and smooth operation of the control instruments. Vibration-dampening, maintenance-free and lubrication-free bearings are used here.

Installation Locations and Advantages of Motion Plastics in Construction Machinery

Linear adjustment displays & seat

- Products: drylin W linear guides or drylin N miniature guides

- Advantages: dry-running, dirt-resistant and robust, durable, quiet operation

Bearing arrangement of master switch

- Products: igubal EGLM spherical bearings

- Advantages: corrosion-resistant, high dampening capacity, impact-resistant

Cable guidance of driver's seat

- Products: E 2.1 energy chains

- Advantages: long service life, very quiet operation, easy filling and assembly

Armrest adjustment

- Products: drylin flat guides

- Advantages: dry-running, dirt-resistant & robust, durable, quiet operation

Bearing arrangement of windshield wiper

- Products: iglide H2 plain bearing

- Advantages: low moisture absorption, corrosion-resistant, highly media-resistant, economical

Tested in the test laboratory for use in the real world

All products are tested for wear and load capacity under real-life conditions in the igus test laboratory, the largest in the industry. The results are incorporated into our service life calculation tools and allow exact durability predictions.

Upon request, igus carries out customer tests to check product use under completely customized conditions.