Ongoing pricing pressure is forcing OEMs and parts suppliers to optimize their costs continually. Low-cost tribo-polymers are a commonly used alternative to expensive metal bearings.

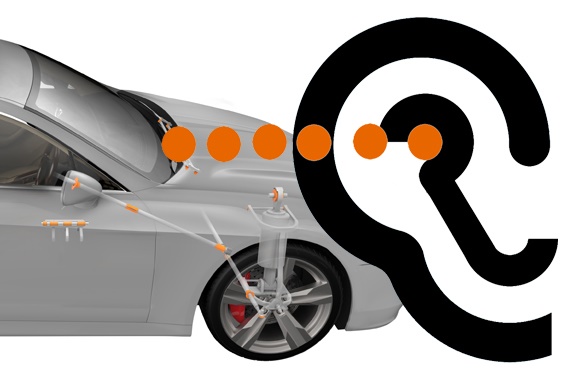

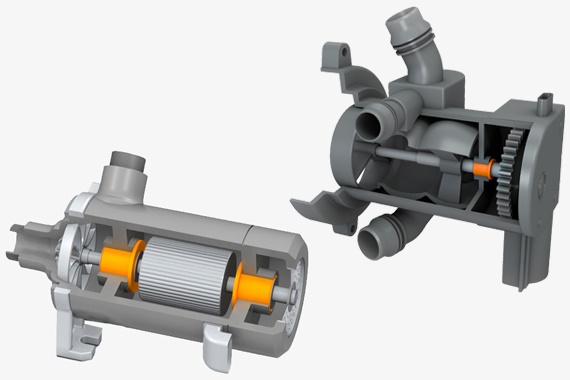

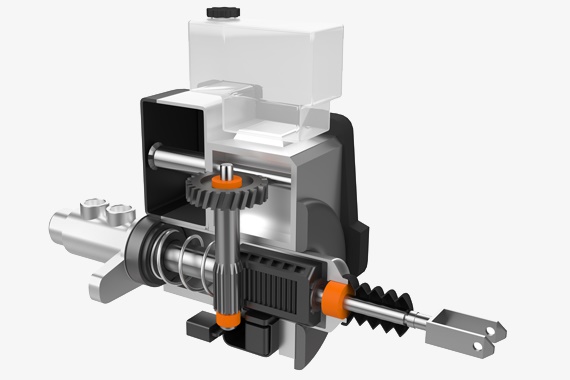

Today, almost every motor vehicle that is made contains polymer bearings as a substitute for metal plain bearings and rolling bearings. Uses range from seat systems to thermally stressful applications within the engine compartment; in shift forks for gearboxes, in coolant pumps, or in the powertrain.

Why are polymer bearings more cost-effective than metal rolled bearings?

BSR are all noises that are produced by components and assemblies in the motor vehicle. The expectations of the OEMs in this context are increasing continually. In the case of alternative drives such as the hybrid or electric motor, the noise of the drive is reduced, as a result of which noises inside the vehicle are masked to a much lesser extent by a loud combustion engine. At the same time, it is becoming quieter and quieter inside motor vehicles.

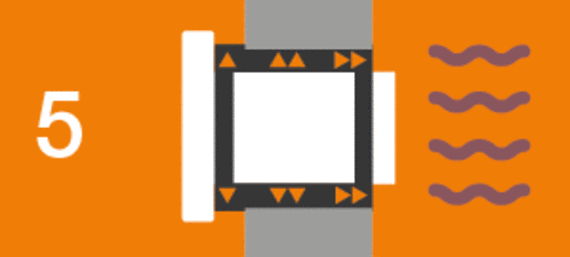

How do iglide® plain bearings reduce noise?

Noises always arise where components interact with each other, in other words where friction occurs. With the tribologically optimised high-performance polymers from igus, you achieve an especially low coefficient of friction and therefore a quiet application. Highly engineered polymers are characterised by the fact that, unlike metal, it has a damping effect. In applications involving severe vibrational stress, a polymer bearing solution helps to reduce noise inside motor vehicles. The range of materials developed by igus includes materials that have especially good damping properties.

Monday to Friday from 8 am - 8 pm

24h