Change Language :

Product range expansion of the dryspin® lead screws

by four new dimensions

Higher efficiency and longer service life than conventional lead screws thanks to the unique dryspin® high helix lead screw technology. Corrosion-free and 100% lubrication-free and maintenance-free.

Our dryspin® lead screws are now available in the four new dimensions:

► DS10x2 RH

► DS12x3 RH

► DS14x4 LH

► DS18x4 LH

Reduce the time required for your design and optimise the lead screw technology procurement process.

The new dimensions of the dryspin® high helix lead screws at a glance

Further important information:

Higher efficiency, longer service life

This is what dryspin® technology can do

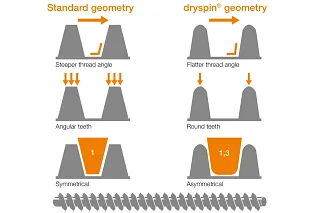

The dryspin high helix thread technology was developed by igus in 2013 and offers numerous advantages compared to conventional high helix threads. Due to the flat thread angle, it efficiently converts the force introduced into a translational movement. With specifications and geometries matched to the plastic nut and spindles, dryspin provides an even longer service life and more efficiency for high helix threads. Due to the rounded tooth geometry, the contact area between lead screw and nut is reduced, and the lead systems operate quietly and without vibration under load.

The larger spaces between the individual dryspin threads result in a higher proportion (factor 1.3) of tribologically optimised polymer in the threads. More wear-resistant material and higher levels of efficiency are crucial for a service life that is up to five times longer compared to conventional high helix threads.

Try out dryspin® technology for yourself

With the help of the free lead screw sample

Holding a real sample in your hands is an important part of understanding your component. We will be happy to send you a sample of our dryspin lead screw drives for this purpose. We have summarised all the specifications and advantages of dryspin lead screw technology in the sample for you. See for yourself and if you have any questions, our experts will be very happy to help.