Change Language :

DryLin® T - Technical data

| Glide bar | |

|---|---|

| Material | Aluminum, extruded profile |

| Materials | AlMgSi0,5 |

| Coating | Hard-anodized aluminum, 50 µm |

| Surface hardness | 500 HV |

| Gliding carriage | |

| Base body | Aluminum, extruded profile |

| Materials | AlMgSi0,5 |

| Coating | Anodized aluminum, E6/EV1 |

| Gliding elements | Maintenance-free bearing material iglide® J |

| Screws and springs | Stainless steel |

| Lid | Plastic (TW-01/TWA-01), Steel (TW-02) |

| Max. speed | 49 f/s |

| Temperature range | -40 °F to +194 °F |

| Table 01: DryLin® – Technical datas |

DryLin® T in application in the packaging industry

Special features

- With low mass inertia and the exclusion of rolling components, high accelerations and - on a short term - extreme speeds up to 98 ft/s are attained.

- DryLin® T linear guide systems operate dry and are thereby insensitive to dirt. Dirt particles cannot embed in lubricants.

- Particularly suitable for use in food, medicine and clean room technologies due to the absence of lubricants in the environment.

- The corrosion resistance makes the DryLin® T linear guide systems suitable for underwater applications

- Trouble-free high-pressure cleaning

- Low vibration and very low noise

- The pairing of the aluminum anodized gliding partners and iglide® J has a particularly low breakaway torque

- DryLin® T is combinable and replaceable with standard ball linear guides

- Please note that it refers to a technical surface. Optical color variations cannot be avoided depending on the coat thickness.

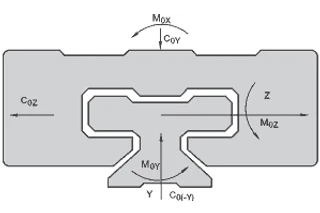

DryLin® T - Permitted static load capacity

| Type | C0Y [kN] | C0(-Y) [kN] | C0Z [kN] | M0X [Nm] | MM0Y [Nm] | M0Z [Nm] |

|---|---|---|---|---|---|---|

| 04-07 | 0,2 | 0,2 | 0,1 | 1,2 | 0,6 | 0,6 |

| 04-09 | 0,48 | 0,48 | 0,24 | 3,4 | 1,8 | 1,8 |

| 04-12 | 0,96 | 0,96 | 0,48 | 9,2 | 4,4 | 4,4 |

| 04-15 | 1,4 | 1,4 | 0,7 | 17 | 8 | 8 |

| 01-15 | 4 | 4 | 2 | 32 | 25 | 25 |

| 01-20 | 7,4 | 7,4 | 3,7 | 85 | 45 | 45 |

| 01-25 | 10 | 10 | 5 | 125 | 65 | 65 |

| 01-30 | 14 | 14 | 7 | 200 | 100 | 100 |

| Table 02: DryLin® - Permitted load capacity, static |

X = Speed v [m/s]

Y = Load F [N]

A = y- direction

B = z- direction

Fig. 02: DryLin® T – Permitted load capacity, dynamic