Change Language :

iglide® tribo-filament for 3D printers

igus® presents world's first tribo filament for 3D printers

igus® presents first tribo filament for 3D printers. The material is up to 50 times more abrasion-resistant than conventional 3D printer materials.

New material is up to 50 times more abrasion-resistant than conventional 3D printer materials

igus® has been researching the 3D printer filament field to provide its customers with even more flexibility. For instance, they can design custom parts or manufacture prototypes while simultaneously relying on the tested service life of igus® materials. The product, which has been tested countless times in the igus® in-house testing lab, is the first filament for 3D printers specifically developed for dynamic applications. This new filament gives customers more flexibility for the design of their bearings, even prototypes can be produced relatively cost-effectively and quickly. igus®' online 3D-CAD library provides access to readily available 3D models for igus® products in STL formats, which can be downloaded and directly used as input data for 3D printing.

The filament will be produced with spool diameters of 1.75 mm and 3.00 mm. There will also be starter kits with approx. 25 g material for initial trials.

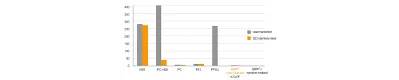

x: wear rate [μm/km]

Wear of pivoting bearings produced using 3D printing: v=0.01 1.97fpm; p= 145psi; ß=60°

Future technology: 3D printer with igus® products – without lubrication

3D printers can print three-dimensional workpieces with computer controls. On one hand advantages include the avoidance of high tooling costs and the fact that no excess material needs to be machined, making 3D printing a cost-effective method. On the other, there are no limits to geometric design, making the production of otherwise impossible and unusual shapes possible.

Reserve a starter kit today: iglide® bearings for in-house 3d printing

iglide® high-performance plastic filament for 3D printers

A new dimension of iglidur® bearing technology

Pre-order a starter kit here.

Would you like to reserve a large quantity of the iglide® tribo-filament? Please contact igus® +1 800 521 2747 or fill out the form below.

Pre-order here

Yes, I would like to pre-order an iglide® tribo-filament starter kit.